Gitee

https://gitee.com/WangXi_Chn/PcComTestApp

应用版本V1.0

应用功能

- 作为应用程序编写范例,可作为模板参考

- 可与上位机通信(遵从板级串口通信模块的通信协议)

- 支持JC24B无线串口透传模块

- 支持HMI界面数据显示

- 支持与其他STM32单片机通信(遵从板级串口通信模块的通信协议)

- 支持LED频闪显示自身ID

开发环境

CubeMX

MDK5 IDE

STM32F103C8T6 芯片

Stm32最小系统板

RT-Thread操作系统

面向对象模块接口设计

陶晶驰HMI串口屏

JC24B无线串口应用特性

模块化设计自由裁剪

多线程工作

通信模块通用,分自身ID和目标ID,可迅速部署通信网络

数据表大小0xFF个int类型数据源文件

App_PcComTest.c

```c /*- Copyright (c) 2020 - ~, HIT_HERO Team *

- PCCOMTEST APP SOUCE FILE

- Used in RT-Thread Operate System *

- Change Logs:

- Date Author Notes Mail

- 2020-09-06 WangXi first version WangXi_chn@foxmail.com */

include “App_PcComTest.h”

include

static void APP_PcComTestInit(APP_PCCOMTEST Application); static void APP_PcComTestRun(APP_PCCOMTEST Application);

static void PcComTestLed_entry(void parameter); static void PcComTestUpdate_entry(void parameter); static void PcComTestDeal_entry(void *parameter);

void APP_PcComTest_Config(APP_PCCOMTEST *Application) { if( Application->Method_Init == NULL && Application->Method_Run == NULL

){/* Link the Method */Application->Method_Init = APP_PcComTestInit;Application->Method_Run = APP_PcComTestRun;}else{rt_kprintf("Warning: Module Led is Configed twice\n");return;}/* Device Init */Application->Method_Init(Application);/* Module Config */Module_UartCom_Config(&(Application->dev_UartBsp));Module_Led_Config(&(Application->dev_Led));Module_UartHMI_Config(&(Application->dev_UartHMI));return;

}

static void APP_PcComTestInit(APP_PCCOMTEST Application) { / Module param list ————————————————————————————————————- / / LED Pin device / / Pin: PC13 Low power enable */ Application->dev_Led.Property_pin = GET_PIN(C, 13); Application->dev_Led.Property_Mode = FLASH_LED_MODE; Application->dev_Led.LED_TIME_CYCLE = 1500; Application->dev_Led.LED_TIME_OUTPUT = 150;

/* JC24B 2.4G Uart communication device *//* Pin: PA2 Uart2_TX *//* Pin: PA3 Uart2_RX *//* Pin: PB12 Set Pin */Application->dev_UartBsp.Property_UartDevName = "uart2";Application->dev_UartBsp.Property_BaudRate = 9600;Application->dev_UartBsp.Property_MyID = MYID;Application->dev_UartBsp.Property_NetID = 0x10;Application->dev_UartBsp.Property_Device = JC24B;Application->dev_UartBsp.Property_JC24BsetPin = GET_PIN(B, 12);/* HMI Uart communication device *//* Pin: PB10 Uart3_TX *//* Pin: PB11 Uart3_RX */Application->dev_UartHMI.Property_UartDevName = "uart3";/* Data Sheet Default Value ------------------------------------------------------------------ */

}

static void APP_PcComTestRun(APP_PCCOMTEST Application)

{

/ Let the LED flash module show the machine ID */

Application->dev_Led.Method_Set(&Application->dev_Led,MYID);

rt_thread_t PcComTestLed_thread = rt_thread_create("PcComTestLed", PcComTestLed_entry,Application,512, RT_THREAD_PRIORITY_MAX - 2, 20);if (PcComTestLed_thread != RT_NULL){rt_thread_startup(PcComTestLed_thread);}rt_thread_t PcComTestUpdate_thread = rt_thread_create("PcComTestUpdate", PcComTestUpdate_entry,Application,512, RT_THREAD_PRIORITY_MAX - 3, 20);if (PcComTestUpdate_thread != RT_NULL){rt_thread_startup(PcComTestUpdate_thread);}rt_thread_t PcComTestDeal_thread = rt_thread_create("PcComTestDeal", PcComTestDeal_entry,Application,1024, RT_THREAD_PRIORITY_MAX - 3, 20);if (PcComTestDeal_thread != RT_NULL){rt_thread_startup(PcComTestDeal_thread);}

}

/ thread entry list ——————————————————————————————————————- /

static void PcComTestLed_entry(void parameter)

{

APP_PCCOMTEST Application = (APP_PCCOMTEST *)parameter;

while(1)

{

rt_thread_mdelay(1);

Application->dev_Led.Method_Handle(&(Application->dev_Led));

}

}

static void PcComTestUpdate_entry(void parameter) { APP_PCCOMTEST Application = (APP_PCCOMTEST *)parameter;

Application->dev_UartBsp.Method_Feed( &(Application->dev_UartBsp),&(Application->Value_PacketID),Application->Value_DataSheet);

}

static void PcComTestDeal_entry(void parameter) { APP_PCCOMTEST Application = (APP_PCCOMTEST *)parameter; char str[50]; while (1) { rt_thread_mdelay(1); sprintf(str, “tempreture.txt=\”%d\””, Application->Value_DataSheet[gytempreture_ID]); Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);

sprintf(str, "offsetdata.txt=\"%d\"", Application->Value_DataSheet[gylingdata_ID]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "origindata.txt=\"%d\"", Application->Value_DataSheet[qystartdata_ID]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "dealdata.txt=\"%d\"", Application->Value_DataSheet[gylvdata_ID]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "groAngle.txt=\"%d\"", Application->Value_DataSheet[gyangle_ID]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "sampleNum.txt=\"%d\"", Application->Value_DataSheet[maNumber]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magXorigin.txt=\"%d\"", Application->Value_DataSheet[ma]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magXdeal.txt=\"%d\"", Application->Value_DataSheet[malvX]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magYorigin.txt=\"%d\"", Application->Value_DataSheet[mastartY]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magYdeal.txt=\"%d\"", Application->Value_DataSheet[malvY]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magXoffset.txt=\"%d\"", Application->Value_DataSheet[malingX]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magYoffset.txt=\"%d\"", Application->Value_DataSheet[malingY]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magCircle.txt=\"%d\"", Application->Value_DataSheet[macircle]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "magAngle.txt=\"%d\"", Application->Value_DataSheet[maAngle]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "AimX.txt=\"%d\"", Application->Value_DataSheet[coX]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "AimY.txt=\"%d\"", Application->Value_DataSheet[coY]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "AimR.txt=\"%d\"", Application->Value_DataSheet[coangle]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "Mode.txt=\"%d\"", Application->Value_DataSheet[mo360]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "GPSX.txt=\"%d\"", Application->Value_DataSheet[allX]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "GPSY.txt=\"%d\"", Application->Value_DataSheet[allY]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);sprintf(str, "GPSAng.txt=\"%d\"", Application->Value_DataSheet[allziangle]);Application->dev_UartHMI.Method_Send(&Application->dev_UartHMI,str);}

}

/** (C) COPYRIGHT 2020 WANGXI **END OF FILE**/

- 方法API解释- 在Config全局函数中,实现对应用对象的初始化- 绑定函数方法,调用Init初始化方法(配置成员模块的必要参数,初始化数据表默认数值)- 调用各个模块的Config全局函数,实现对各个模块的初始化- Run方法被main调用,指示应用开始运行- 调用成员模块的方法,执行外设功能- 创建线程,启动线程- 初始化所需信号量等- 线程解释- PcComTestLed- 应用状态灯线程,通过频闪次数指示自身在网中的ID号- PcComTestUpdate- 数据更新线程,接收串口数据更新数据表- PcComTestDeal- 数据处理线程,这里仅将数据表中的信息对应显示在了串口屏中<a name="hACgS"></a>#### App_PcComTest.h```c/** Copyright (c) 2020 - ~, HIT_HERO Team** PCCOMTEST APP HEAD FILE* Used in RT-Thread Operate System** Change Logs:* Date Author Notes Mail* 2020-09-06 WangXi first version WangXi_chn@foxmail.com*/#ifndef _APP_PCCOMTEST_H_#define _APP_PCCOMTEST_H_#include <rtthread.h>#include <rtdevice.h>#include <board.h>#include "Module_UartCom.h"#include "Module_LED.h"#include "Module_UartHMI.h"struct _APP_PCCOMTEST{/* Property */MODULE_UARTCOM dev_UartBsp;MODULE_LED dev_Led;MODULE_UARTHMI dev_UartHMI;/* Value */UARTCOM_PACKETID Value_PacketID;rt_int32_t Value_DataSheet[0xFF];/* Method */void (*Method_Init)(struct _APP_PCCOMTEST *Application);void (*Method_Run)(struct _APP_PCCOMTEST *Application);};typedef struct _APP_PCCOMTEST APP_PCCOMTEST;void APP_PcComTest_Config(APP_PCCOMTEST *Application);//Machine_ID define--------------------------------------------------------------#define MYID 0x01#define PCID 0x11//Packet_ID define---------------------------------------------------------------//陀螺仪//陀螺仪芯片温度 gytempreture 0X01#define gytempreture_ID 0x01//陀螺仪Z轴零偏数据 gylingdata 0X02#define gylingdata_ID 0x02//陀螺仪Z轴原始数据 qystartdata 0X03#define qystartdata_ID 0X03//陀螺仪Z轴滤波数据 gylvdata 0X04#define gylvdata_ID 0X04//陀螺仪计算角度 gyangle 0X05#define gyangle_ID 0X05//陀螺仪Kalman滤波器参数 估算协方差P gyP 0X06#define gyP 0x06//陀螺仪Kalman滤波器参数 过程噪声协方差Q gyQ 0X07#define gyQ 0X07//陀螺仪Kalman滤波器参数 观测噪声协方差R gyR 0X08#define gyR 0X08//磁力计//磁位计X轴原始数据 ma 0X11#define ma 0X11//磁位计X轴滤波数据 malvX 0X12#define malvX 0X12//磁位计Y轴原始数据 mastartY 0X13#define mastartY 0X13//磁位计Y轴滤波数据 malvY 0X14#define malvY 0X14//磁位计计算角度 maAngle 0X15#define maAngle 0X15//设置零偏采样值个数 maNumber 0X16#define maNumber 0X16//磁位计X轴零偏数据 malingX 0X17#define malingX 0X17//磁位计Y轴零偏数据 malingY 0X18#define malingY 0X18//磁位计圆化率 macircle 0X19#define macircle 0X19//磁位计Kalman滤波器参数 估算协方差P maP 0X1A#define maP 0X1A//磁位计Kalman滤波器参数 过程噪声协方差Q maQ 0X1B#define maQ 0X1B//磁位计Kalman滤波器参数 观测噪声协方差R maR 0X1C#define maR 0X1C//整体部分读取//互补滤波角度 allangle 0X21#define allangle 0X21//全局定位X坐标值 allX 0X22#define allX 0x22//全局定位Y坐标值 allY 0X23#define allY 0x23//全局定位姿态角值 allziangle 0X24#define allziangle 0X24//模式部分//选择360° mo360 0X31#define mo360 0X31//±180°模式 mo180 0X32#define mo180 0X32//控制部分读取//装置目标位置值 cogoallocation 0X41#define cogoallocation 0X41//装置实际位置值 coactuallocation 0X42#define coactuallocation 0X42//装置目标角度值 cogoalangle 0X43#define cogoalangle 0X43//装置实际位置值 coactualangle 0X44#define coactualangle 0X44//装置坐标值X coX 0X45#define coX 0X45//装置坐标值Y coY 0X46#define coY 0X46//装置姿态角 coangle 0X47#define coangle 0X47#endif/************************ (C) COPYRIGHT 2020 WANGXI **************END OF FILE****/

- 将帧的ID作为数据表(数组)的检索,对数据表读取或存储

使用main.c

```c /*- Copyright (c) 2020 - ~, HIT_HERO Team *

- STM32F103C8T6 MIN SYSTEM MAIN SOUCE FILE

- Used in RT-Thread Operate System *

- Change Logs:

- Date Author Notes Mail

- 2020-09-03 WangXi first version WangXi_chn@foxmail.com *

- Note:

- Finsh: uart1

- uart1_tx —> PA9

- uart1_rx —> PA10 */

include

include

include

include “App_PcComTest.h”

APP_PCCOMTEST app_pccomtest;

int main(void) { APP_PcComTest_Config(&app_pccomtest); app_pccomtest.Method_Run(&app_pccomtest);

return 0;

}

/** (C) COPYRIGHT 2020 WANGXI **END OF FILE**/

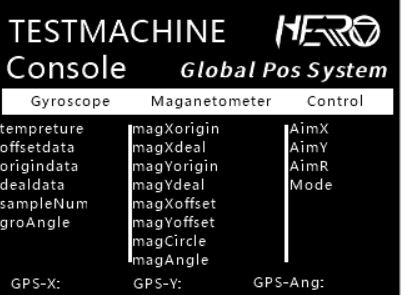

屏幕界面

显示屏程序

TJC3224T022_011_TESTMACH.rar

补充说明

- 该应用程序并非正式投入使用的程序,只是各项功能的先行验证版本

- 同时也是通过应用封装各个模块的模板说明,为如何组织各个模块工作提供范例

- 将视情况选择是否继续更新

应用版本V2.0

功能更新

- 赋予项目名称 Ratel(蜜獾)

- 寓意勇敢尝试,实验新的功能

- 试验了无线串口通信的组网功能

- 试验了通过单片机自定义ID的功能

- 试验了OLED显示功能