Gitee

https://gitee.com/WangXi_Chn/RttOs_ModuleLib

开发环境

CubeMX

MDK5 IDE

STM32F407IGH6TR 芯片

大疆开发板 C型

大疆M3508直流无刷电机

大疆C620无刷电机调速器

RT-Thread操作系统

面向对象模块接口设计

硬件条件

- 确保Can线供电电平达到5V(不可仅使用JTAG接口供电3.3V)

-

添加驱动

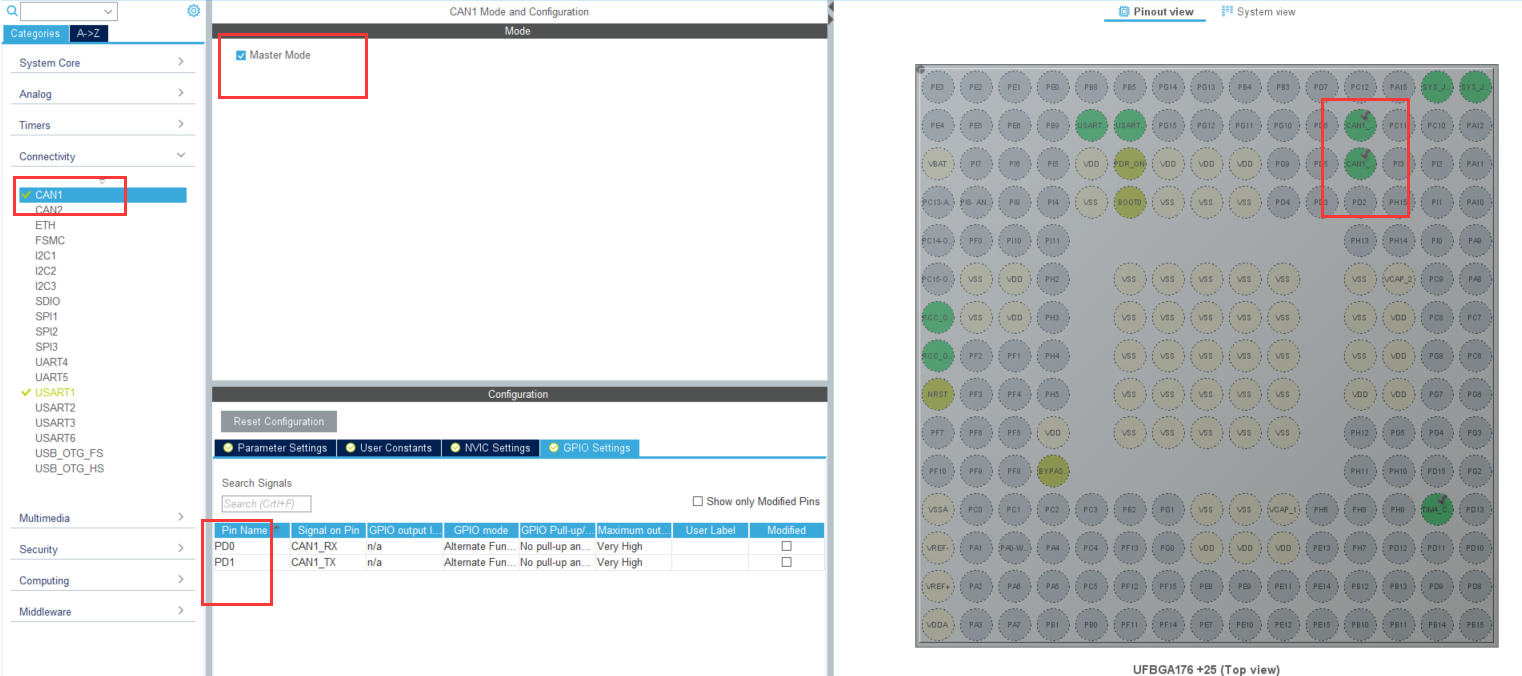

CubuMX

使能Can1

配置引脚(使能的自动引脚配置可能错误,需要在右侧引脚单独点击使能)

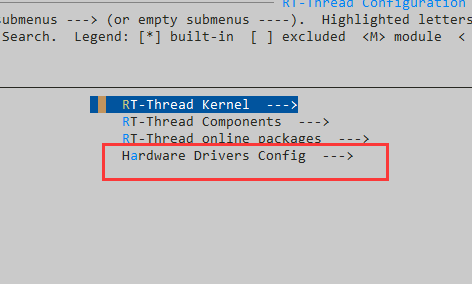

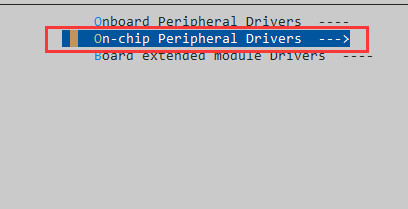

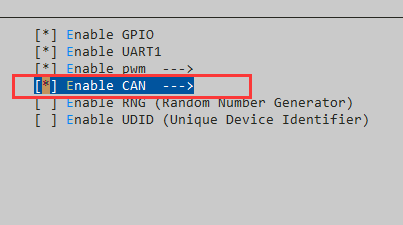

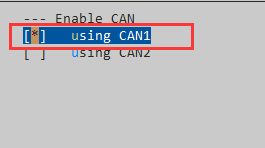

Kconfig

menuconfig BSP_USING_CANbool "Enable CAN"default nselect RT_USING_CANif BSP_USING_CANconfig BSP_USING_CAN1bool "using CAN1"default nconfig BSP_USING_CAN2bool "using CAN2"default nendif

Env

使能CAN1驱动

-

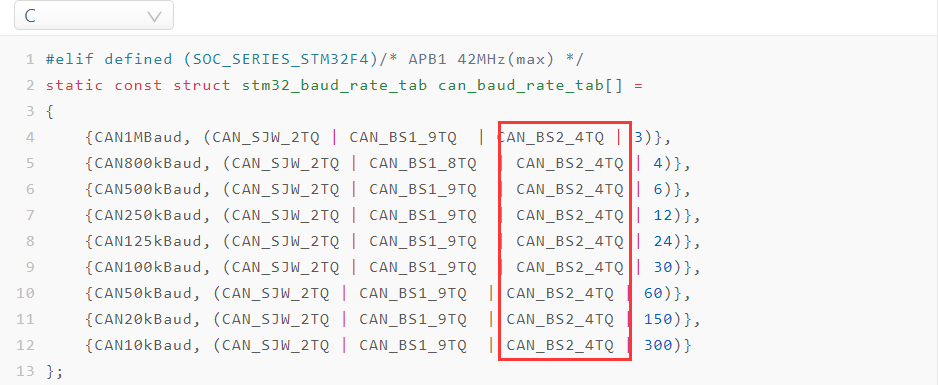

修改时钟

STM32F407的APB1总线一般是42MHz,但是RT-Thread波特率选项默认为45MHz

需要修改

drv_can.c文件为如下内容#elif defined (SOC_SERIES_STM32F4)/* APB1 42MHz(max) */static const struct stm32_baud_rate_tab can_baud_rate_tab[] ={{CAN1MBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 3)},{CAN800kBaud, (CAN_SJW_2TQ | CAN_BS1_8TQ | CAN_BS2_4TQ | 4)},{CAN500kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 6)},{CAN250kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 12)},{CAN125kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 24)},{CAN100kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 30)},{CAN50kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 60)},{CAN20kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 150)},{CAN10kBaud, (CAN_SJW_2TQ | CAN_BS1_9TQ | CAN_BS2_4TQ | 300)}};

注意这个位置

接口函数

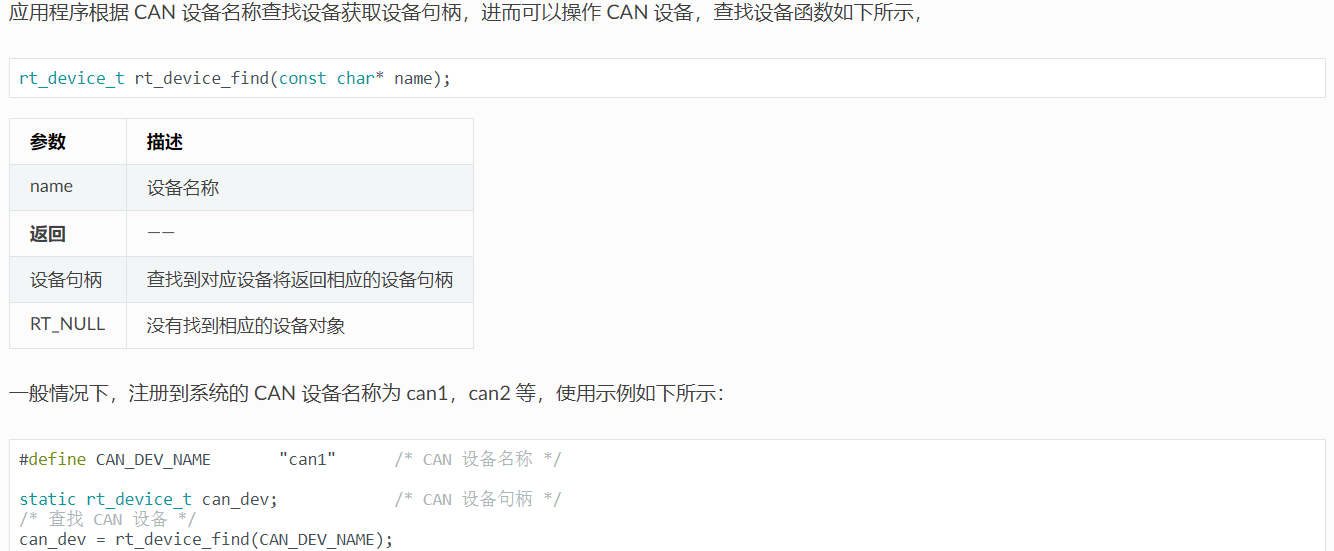

查找设备

打开设备

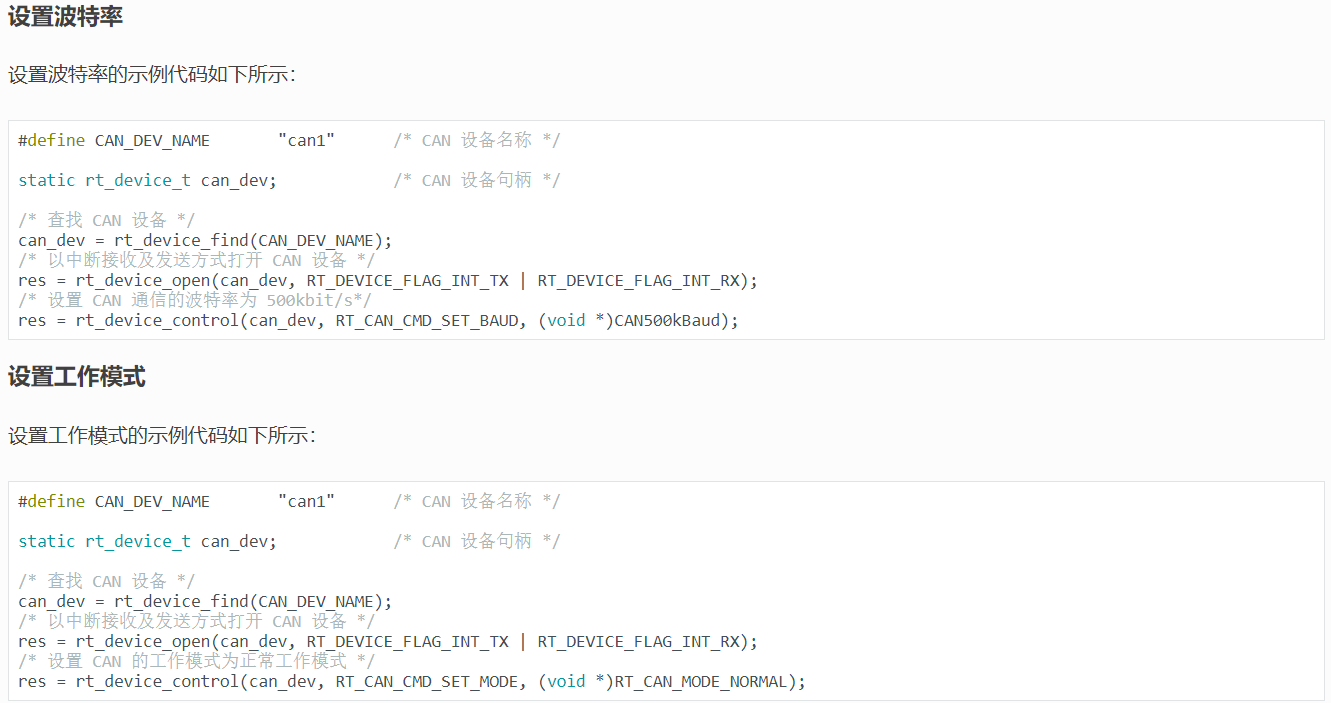

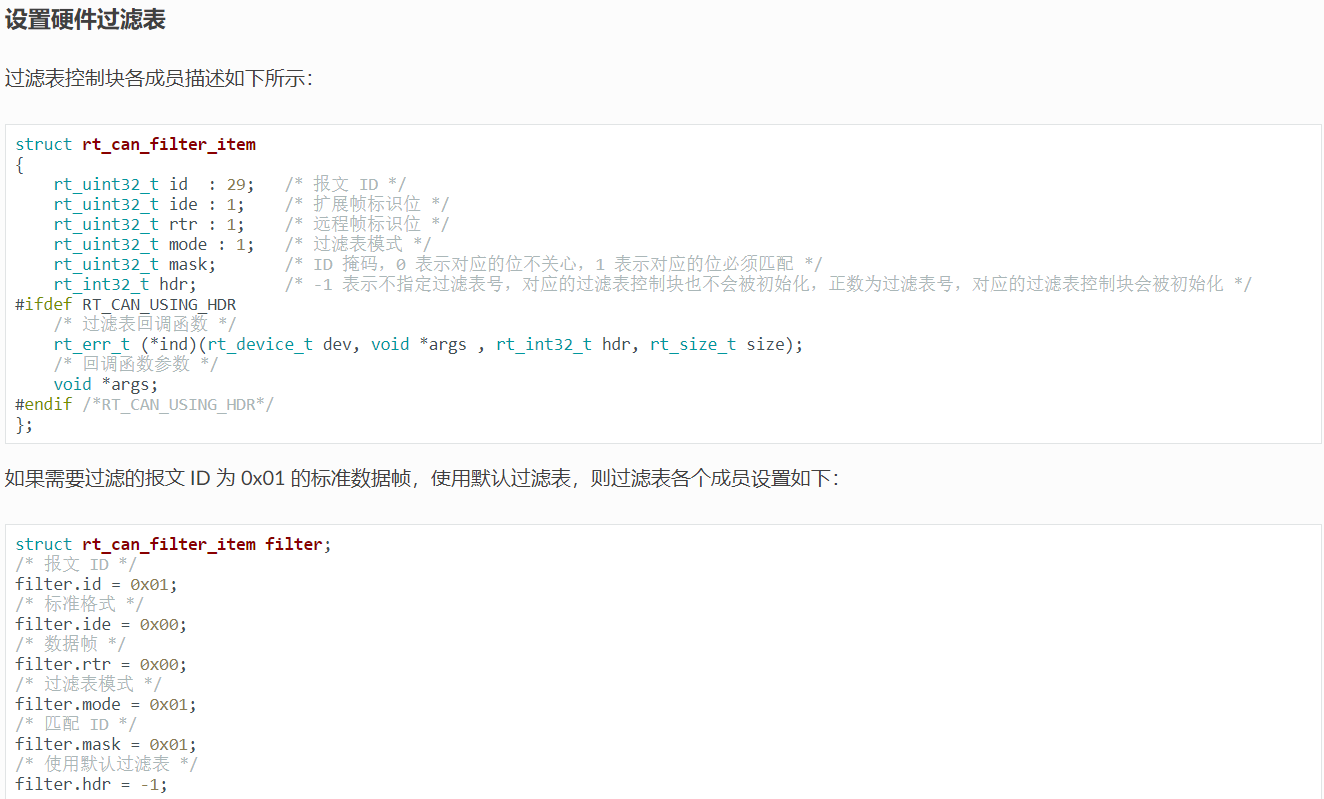

控制设备

发送数据

设置接收回调

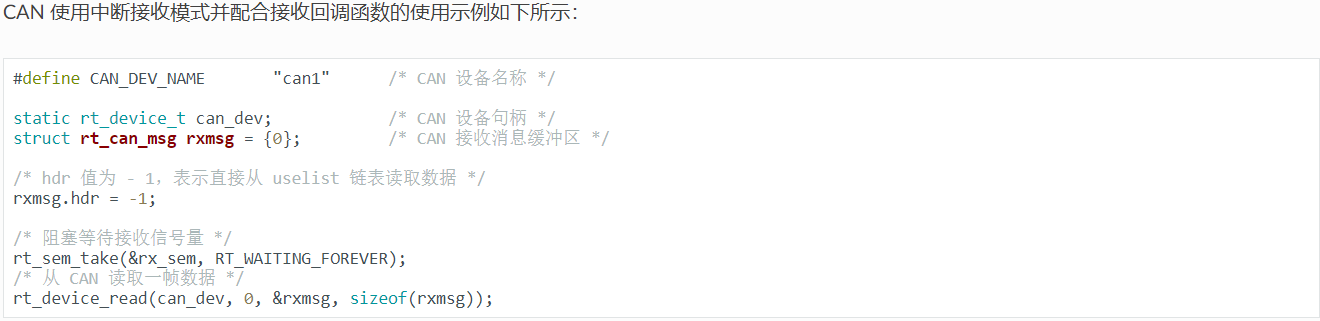

接收数据

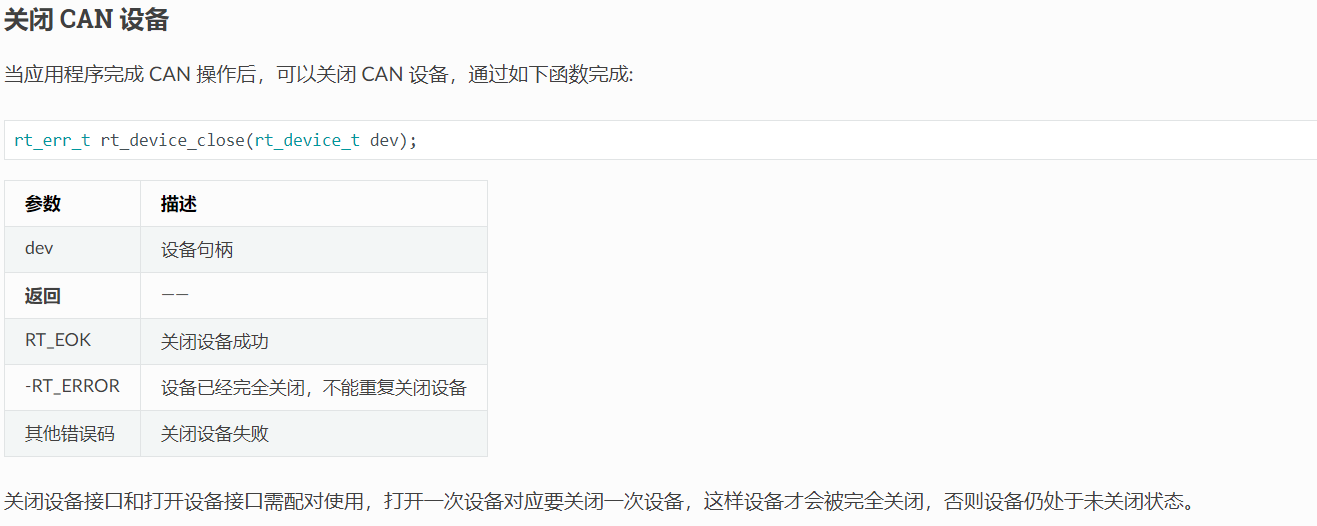

关闭设备

官方例程

/** 程序清单:这是一个 CAN 设备使用例程* 例程导出了 can_sample 命令到控制终端* 命令调用格式:can_sample can1* 命令解释:命令第二个参数是要使用的 CAN 设备名称,为空则使用默认的 CAN 设备* 程序功能:通过 CAN 设备发送一帧,并创建一个线程接收数据然后打印输出。*/#include <rtthread.h>#include "rtdevice.h"#define CAN_DEV_NAME "can1" /* CAN 设备名称 */static struct rt_semaphore rx_sem; /* 用于接收消息的信号量 */static rt_device_t can_dev; /* CAN 设备句柄 *//* 接收数据回调函数 */static rt_err_t can_rx_call(rt_device_t dev, rt_size_t size){/* CAN 接收到数据后产生中断,调用此回调函数,然后发送接收信号量 */rt_sem_release(&rx_sem);return RT_EOK;}static void can_rx_thread(void *parameter){int i;rt_err_t res;struct rt_can_msg rxmsg = {0};/* 设置接收回调函数 */rt_device_set_rx_indicate(can_dev, can_rx_call);#ifdef RT_CAN_USING_HDRstruct rt_can_filter_item items[5] ={RT_CAN_FILTER_ITEM_INIT(0x100, 0, 0, 1, 0x700, RT_NULL, RT_NULL), /* std,match ID:0x100~0x1ff,hdr 为 - 1,设置默认过滤表 */RT_CAN_FILTER_ITEM_INIT(0x300, 0, 0, 1, 0x700, RT_NULL, RT_NULL), /* std,match ID:0x300~0x3ff,hdr 为 - 1 */RT_CAN_FILTER_ITEM_INIT(0x211, 0, 0, 1, 0x7ff, RT_NULL, RT_NULL), /* std,match ID:0x211,hdr 为 - 1 */RT_CAN_FILTER_STD_INIT(0x486, RT_NULL, RT_NULL), /* std,match ID:0x486,hdr 为 - 1 */{0x555, 0, 0, 1, 0x7ff, 7,} /* std,match ID:0x555,hdr 为 7,指定设置 7 号过滤表 */};struct rt_can_filter_config cfg = {5, 1, items}; /* 一共有 5 个过滤表 *//* 设置硬件过滤表 */res = rt_device_control(can_dev, RT_CAN_CMD_SET_FILTER, &cfg);RT_ASSERT(res == RT_EOK);#endifwhile (1){/* hdr 值为 - 1,表示直接从 uselist 链表读取数据 */rxmsg.hdr = -1;/* 阻塞等待接收信号量 */rt_sem_take(&rx_sem, RT_WAITING_FOREVER);/* 从 CAN 读取一帧数据 */rt_device_read(can_dev, 0, &rxmsg, sizeof(rxmsg));/* 打印数据 ID 及内容 */rt_kprintf("ID:%x", rxmsg.id);for (i = 0; i < 8; i++){rt_kprintf("%2x", rxmsg.data[i]);}rt_kprintf("\n");}}int can_sample(int argc, char *argv[]){struct rt_can_msg msg = {0};rt_err_t res;rt_size_t size;rt_thread_t thread;char can_name[RT_NAME_MAX];if (argc == 2){rt_strncpy(can_name, argv[1], RT_NAME_MAX);}else{rt_strncpy(can_name, CAN_DEV_NAME, RT_NAME_MAX);}/* 查找 CAN 设备 */can_dev = rt_device_find(can_name);if (!can_dev){rt_kprintf("find %s failed!\n", can_name);return RT_ERROR;}/* 初始化 CAN 接收信号量 */rt_sem_init(&rx_sem, "rx_sem", 0, RT_IPC_FLAG_FIFO);/* 以中断接收及发送方式打开 CAN 设备 */res = rt_device_open(can_dev, RT_DEVICE_FLAG_INT_TX | RT_DEVICE_FLAG_INT_RX);RT_ASSERT(res == RT_EOK);/* 创建数据接收线程 */thread = rt_thread_create("can_rx", can_rx_thread, RT_NULL, 1024, 25, 10);if (thread != RT_NULL){rt_thread_startup(thread);}else{rt_kprintf("create can_rx thread failed!\n");}msg.id = 0x78; /* ID 为 0x78 */msg.ide = RT_CAN_STDID; /* 标准格式 */msg.rtr = RT_CAN_DTR; /* 数据帧 */msg.len = 8; /* 数据长度为 8 *//* 待发送的 8 字节数据 */msg.data[0] = 0x00;msg.data[1] = 0x11;msg.data[2] = 0x22;msg.data[3] = 0x33;msg.data[4] = 0x44;msg.data[5] = 0x55;msg.data[6] = 0x66;msg.data[7] = 0x77;/* 发送一帧 CAN 数据 */size = rt_device_write(can_dev, 0, &msg, sizeof(msg));if (size == 0){rt_kprintf("can dev write data failed!\n");}return res;}/* 导出到 msh 命令列表中 */MSH_CMD_EXPORT(can_sample, can device sample);

适配模块接口

Module_3508Motor.h

/** Copyright (c) 2020 - ~, HIT_HERO Team** 2508MOTOR_CAN MODULE HEAD FILE* Used in RT-Thread Operate System** Change Logs:* Date Author Notes Mail* 2020-08-02 WangXi first version WangXi_chn@foxmail.com*/#ifndef _MODULE_3508MOTOR_H_#define _MODULE_3508MOTOR_H_#include <rtthread.h>#include <rtdevice.h>#include <board.h>#include "Math_PID.h"struct _MODULE_MOTOR3508{/* Property */char * CanDevName;rt_uint32_t MOTOR3508ID_HEAD;rt_uint32_t MOTOR3508ID_NUM;rt_uint32_t MOTOR3508ID_FEED;MATH_PID Motor3508_PID;/* Value */rt_device_t can_dev;struct rt_can_msg can_msg;struct rt_can_msg can_mrg;rt_int32_t motor_AimCurrent;rt_int32_t motor_AimAngSpeed;rt_int32_t motor_AimAngle;rt_int32_t motor_RealCurrent;rt_int32_t motor_RealAngSpeed;rt_int32_t motor_RealAngle;rt_uint8_t motor_Temperature;/* Method */void (*Init)(struct _MODULE_MOTOR3508 *module);void (*Send)(struct _MODULE_MOTOR3508 *module);void (*Feed)(struct _MODULE_MOTOR3508 *module);rt_err_t (*Handle)(rt_device_t dev,rt_size_t size);};typedef struct _MODULE_MOTOR3508 MODULE_MOTOR3508;/* Glodal Method */rt_err_t Module_Motor3508_Config(MODULE_MOTOR3508 *Dev_Motor3508);#endif/************************ (C) COPYRIGHT 2020 WANGXI **************END OF FILE****/

Module_3508Motor.c

/** Copyright (c) 2020 - ~, HIT_HERO Team** 2508MOTOR_CAN MODULE SOUCE FILE* Used in RT-Thread Operate System** Change Logs:* Date Author Notes Mail* 2020-08-02 WangXi first version WangXi_chn@foxmail.com*/#include "Module_3508Motor.h"/* User Code Begin*//* User Code End *//* Static Method */static void Module_Motor3508Init(MODULE_MOTOR3508 *module);static void Module_Motor3508Send(MODULE_MOTOR3508 *module);static void Module_Motor3508Feed(MODULE_MOTOR3508 *module);static rt_err_t Module_Motor3508Handle(rt_device_t dev, rt_size_t size);static struct rt_semaphore can_sem;/* Global Method */rt_err_t Module_Motor3508_Config(MODULE_MOTOR3508 *Dev_Motor3508){if( Dev_Motor3508->Init ==NULL &&Dev_Motor3508->Handle ==NULL &&Dev_Motor3508->Send ==NULL &&Dev_Motor3508->Feed ==NULL){/* Link the Method */Dev_Motor3508->Init = Module_Motor3508Init;Dev_Motor3508->Handle = Module_Motor3508Handle;Dev_Motor3508->Send = Module_Motor3508Send;Dev_Motor3508->Feed = Module_Motor3508Feed;}else{rt_kprintf("Warning: Module Motor 3508 is Configed twice\n");return RT_ERROR;}/* Device Init */Dev_Motor3508->Init(Dev_Motor3508);/* Module PID controler Init */Module_PID_Config(&(Dev_Motor3508->Motor3508_PID));return RT_EOK;}/* Static Method */static void Module_Motor3508Init(MODULE_MOTOR3508 *module){rt_err_t res;/* link can devices */module->can_dev = rt_device_find(module->CanDevName);if (!module->can_dev)rt_kprintf("find %s failed!\n", module->CanDevName);/* init semaphone */rt_sem_init(&can_sem, "can_sem", 0, RT_IPC_FLAG_FIFO);res = rt_device_open(module->can_dev, RT_DEVICE_FLAG_INT_TX | RT_DEVICE_FLAG_INT_RX);RT_ASSERT(res == RT_EOK);/* set up hardware filter */struct rt_can_filter_item items[1] ={// id ide rtr mode mask hdr{ module->MOTOR3508ID_FEED, 0, 0, 1, 0xFFFF, 1 }};struct rt_can_filter_config cfg = {1, 1, items};res = rt_device_control(module->can_dev, RT_CAN_CMD_SET_FILTER, &cfg);RT_ASSERT(res == RT_EOK);/* set up can baudrate */rt_device_control(module->can_dev, RT_CAN_CMD_SET_BAUD, (void *)CAN1MBaud);/* send frame preprocess */module->can_msg.id = module->MOTOR3508ID_HEAD;module->can_msg.ide = RT_CAN_STDID;module->can_msg.rtr = RT_CAN_DTR;module->can_msg.len = 8;/* feed frame preprocess */module->can_mrg.hdr = 1;res = rt_device_control(module->can_dev, RT_CAN_CMD_SET_MODE, (void *)RT_CAN_MODE_NORMAL);RT_ASSERT(res == RT_EOK);/* link call back function */rt_device_set_rx_indicate(module->can_dev, module->Handle);}static void Module_Motor3508Send(MODULE_MOTOR3508 *module){rt_size_t size;module->motor_AimCurrent = module->Motor3508_PID.Value_out;/* limit output */module->motor_AimCurrent = module->motor_AimCurrent > 16384? 16384 : module->motor_AimCurrent;module->motor_AimCurrent = module->motor_AimCurrent < -16384? -16384 : module->motor_AimCurrent;if(module->MOTOR3508ID_HEAD == 0x200){module->can_msg.data[module->MOTOR3508ID_NUM*2-1]=module->motor_AimCurrent&0XFF;module->can_msg.data[module->MOTOR3508ID_NUM*2-2]=module->motor_AimCurrent>>8;}else if(module->MOTOR3508ID_HEAD == 0x1FF){module->can_msg.data[module->MOTOR3508ID_NUM*2-9]=module->motor_AimCurrent&0XFF;module->can_msg.data[module->MOTOR3508ID_NUM*2-10]=module->motor_AimCurrent>>8;}else{rt_kprintf("MOTOR3508ID_HEAD is a wrong number!\n");}size = rt_device_write(module->can_dev, 0, &(module->can_msg), sizeof(module->can_msg));if (size == 0)rt_kprintf("can dev write data failed!\n");}static rt_err_t Module_Motor3508Handle(rt_device_t dev, rt_size_t size){rt_sem_release(&can_sem);return RT_EOK;}static void Module_Motor3508Feed(MODULE_MOTOR3508 *module){rt_sem_take(&can_sem, RT_WAITING_FOREVER);rt_device_read(module->can_dev, 0, &(module->can_mrg), sizeof(module->can_mrg));module->motor_RealAngle = ((module->can_mrg.data[0]<<8) + module->can_mrg.data[1])*360/8189; // °module->motor_RealAngSpeed = ((module->can_mrg.data[2]<<8) + module->can_mrg.data[3])*360/3600; // °/smodule->motor_RealCurrent = ((module->can_mrg.data[4]<<8) + module->can_mrg.data[5]);module->motor_Temperature = module->can_mrg.data[6];module->Motor3508_PID.Method_Update( &(module->Motor3508_PID),module->motor_AimAngSpeed,module->motor_RealAngSpeed,0.5);}/************************ (C) COPYRIGHT 2020 WANGXI **************END OF FILE****/

Math_PID.h

/** Copyright (c) 2020 - ~, HIT_HERO Team** PID MATH MODULE HEAD FILE* Used in RT-Thread Operate System** Change Logs:* Date Author Notes Mail* 2020-08-05 WangXi first version WangXi_chn@foxmail.com*/#include <rtthread.h>#include <rtdevice.h>#include <board.h>#ifndef _MATH_PID_H_#define _MATH_PID_H_struct _MATH_PID{/* Property */float Property_kP;float Property_kI;float Property_kD;float Property_Imax;float Property_outmax;float Property_IerrorMax; //允许积分的最大偏差值/* Value */float Value_dt;float Value_P;float Value_I;float Value_D;float Value_AntiIFactor; //快速退积分系数float Value_set;float Value_feedback;float Value_Lasterror;float Value_error;float Value_derror;float Value_Lastderror; //滤波用float Value_out;/* Method */void (*Method_Init)(struct _MATH_PID *module);void (*Method_Update)(struct _MATH_PID *module,float Aim, float Feedback,double Coafficient);};typedef struct _MATH_PID MATH_PID;rt_err_t Module_PID_Config(MATH_PID *module);#endif/************************ (C) COPYRIGHT 2020 WANGXI **************END OF FILE****/

Math_PID.c

/** Copyright (c) 2020 - ~, HIT_HERO Team** PID MATH MODULE SOUCE FILE* Used in RT-Thread Operate System** Change Logs:* Date Author Notes Mail* 2020-08-05 WangXi first version WangXi_chn@foxmail.com*/#include "Math_PID.h"#include <math.h>static void Module_PIDInit(MATH_PID *module);static void Module_PIDUpdate(MATH_PID *module,float Aim, float Feedback,double Coafficient);static float constrain_float(float amt, float low, float high);/* Global Method */rt_err_t Module_PID_Config(MATH_PID *module){if( module->Method_Init ==NULL &&module->Method_Update ==NULL){/* Link the Method */module->Method_Init = Module_PIDInit;module->Method_Update = Module_PIDUpdate;}else{rt_kprintf("Warning: Module Motor 3508 is Configed twice\n");return RT_ERROR;}/* Device Init */module->Method_Init(module);return RT_EOK;}static void Module_PIDInit(MATH_PID *module){module->Value_AntiIFactor = 1;module->Value_Lastderror = 0;module->Value_P = 0;module->Value_I = 0;module->Value_D = 0;module->Value_error = 0;module->Value_Lasterror = 0;module->Value_derror = 0;module->Value_out = 0;}static void Module_PIDUpdate(MATH_PID *module,float Aim, float Feedback,double Coafficient){module->Value_set = Aim;module->Value_feedback = module->Value_feedback * Coafficient + Feedback * (1 - Coafficient);module->Value_error= module->Value_set - module->Value_feedback;module->Value_derror = ((1.0f - Coafficient) * (module->Value_error - module->Value_Lasterror) + Coafficient * (module->Value_Lastderror));module->Value_Lastderror = module->Value_derror;module->Value_Lasterror = module->Value_error;module->Value_P = module->Property_kP * module->Value_error;if(fabs(module->Value_error) < module->Property_IerrorMax) //如果偏差大于这个,不进行积分{if(fabs((float)(module->Value_I + module->Property_kI * module->Value_error + module->Value_P)) < module->Property_outmax){module->Value_I += (float)(module->Property_kI * module->Value_error * module->Value_AntiIFactor);module->Value_I = constrain_float(module->Value_I, -module->Property_Imax, +module->Property_Imax);}}module->Value_D = module->Property_kD * module->Value_derror;module->Value_out = module->Value_P + module->Value_I + module->Value_D;module->Value_out = constrain_float(module->Value_out, -module->Property_outmax, +module->Property_outmax)/100.0f;}/*** @brief 输出限幅* @param int32_t amt:待输出量* int32_t low:输出最小值* int32_t high:输出最大值* @retval int32_t X:限幅后的输出量*/static float constrain_float(float amt, float low, float high){return ((amt)<(low)?(low):((amt)>(high)?(high):(amt)));}/************************ (C) COPYRIGHT 2020 WANGXI **************END OF FILE****/

使用main.c

#include <rtthread.h>#include <rtdevice.h>#include <board.h>#include "Module_3508Motor.h"MODULE_MOTOR3508 dev_motor3508_1 ={.CanDevName = "can1",.MOTOR3508ID_HEAD = 0x200,.MOTOR3508ID_NUM = 1,.MOTOR3508ID_FEED = 0x201,.Motor3508_PID ={.Property_kP = 15,.Property_kI = 3,.Property_kD = 50,.Property_Imax = 500,.Property_outmax = 1638400,.Property_IerrorMax = 5000}};static void motor_entry(void *parameter){while (1){dev_motor3508_1.Feed(&dev_motor3508_1);rt_thread_mdelay(5);dev_motor3508_1.Send(&dev_motor3508_1);}}int main(void){Module_Motor3508_Config(&dev_motor3508_1);dev_motor3508_1.motor_AimAngSpeed = 5;/* system running motor control */rt_thread_t motor_thread = rt_thread_create("motor", motor_entry, RT_NULL,1024, RT_THREAD_PRIORITY_MAX - 3, 20);if (led_thread != RT_NULL){rt_thread_startup(motor_thread);}}

部分解释

- 模块头文件中的Property注释下的变量为属性,是结构体声明时必须定义的数值,否则无法正常工作

- 模块头文件中的Value注释下的变量为中间变量,是计算过程中的必要数值,可能是输入记录或输出等,可用来调试修改和观察,其初始化赋值在模块的初始化函数中自动进行

- 模块头文件中的Method注释下的变量为函数指针,是该模块提供的函数方法,可通过结构体变量访问成员直接调用

- 模块在使用前必须通过提供的全局方法(Global Method)处理,主要作用是绑定方法函数,初始化变量,初始化驱动,使能外设等

目前电机刷入电流、读出数据功能可正常使用,但PID参数和算法还需要调整,慎重使用

优势

面向对象设计,大大减少全局变量,宏定义等量,近乎没有,移植性强

- 将PID模块嵌入到电机模块中

- PID模块暂未得到实际测试,算法和参数正确与否不确定,但代码结构固定

- Can接收中断仅释放信号量,在线程中处理接收数据,比在中断中处理数据更安全

- 对模块内的函数static静态保护,实现切实的封装,仅可通过访问结构体变量调用函数

-

存在问题

单电机驱动仅修改电机ID即可

- 但驱动多个电机时,Can外设会被多次开启,RTT操作系统报错

- 驱动多电机时,控制帧是一个电机一个电机发送,控制效率低,不符合M3508报文设计

- 接受多电机返回数据时会发生报文错乱

- 电机PID控制缺少验证,而且不满足速度闭环角度闭环的需求

- 以上问题均在下一节中的电机群设计解决