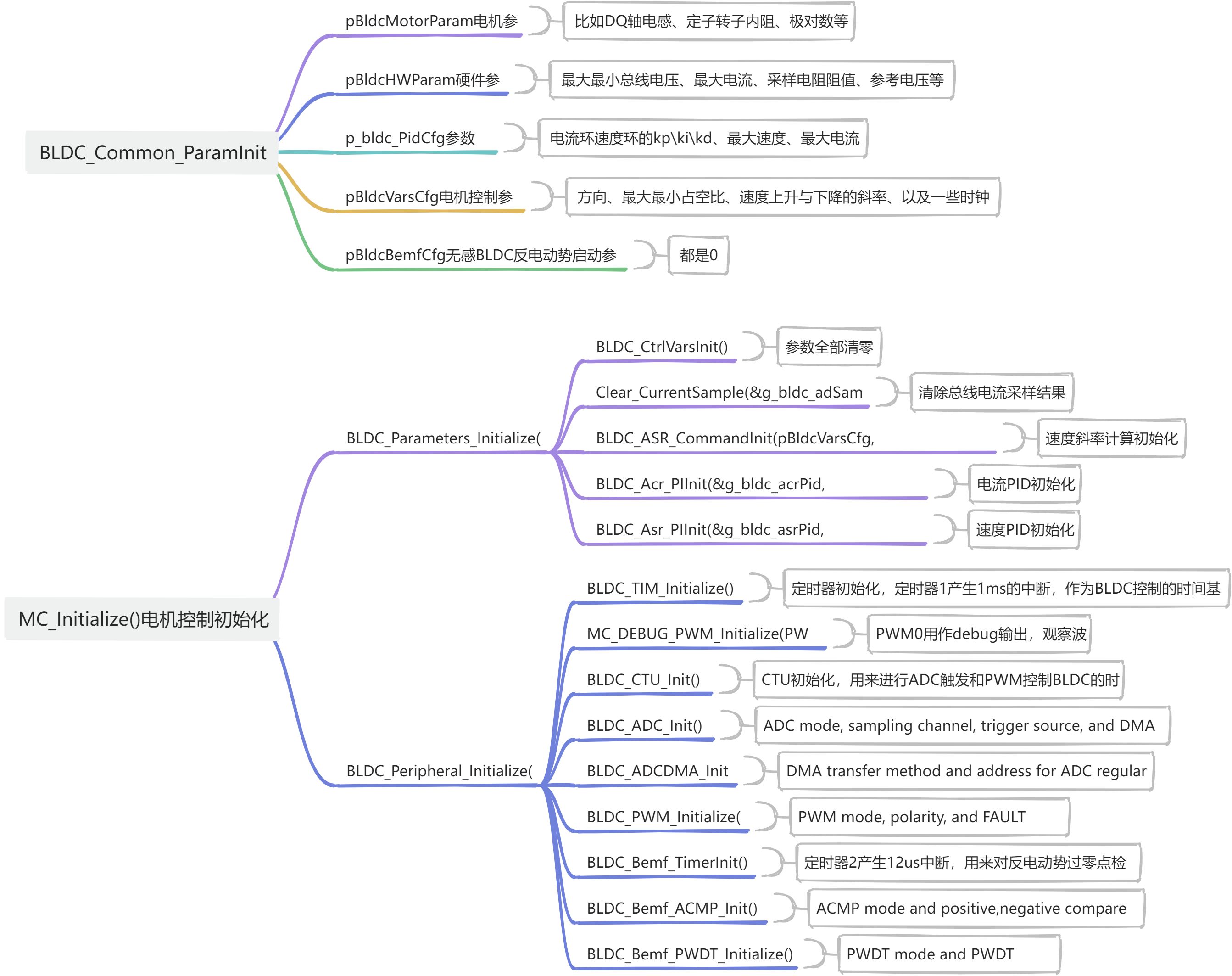

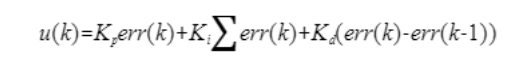

BLDC控制框图

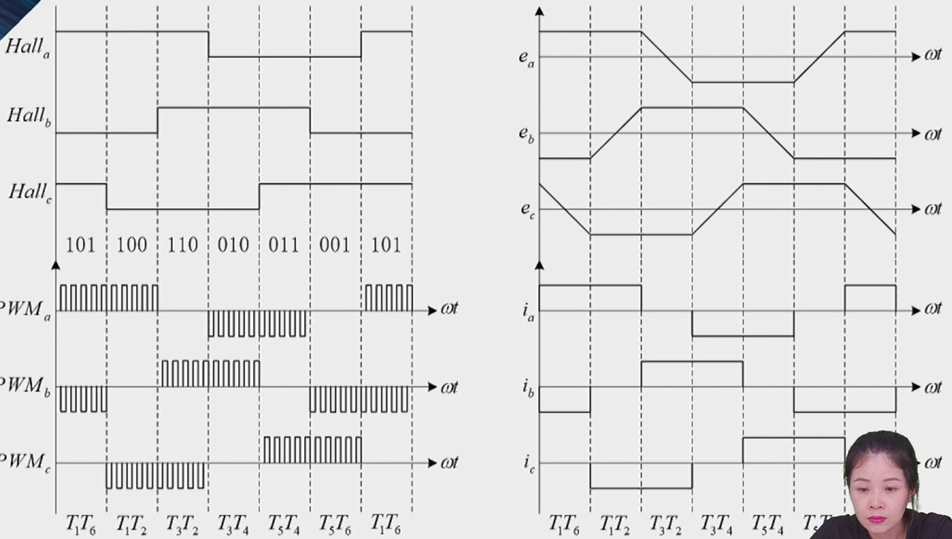

BLDC 的控制电路对电机转子位置信号进行逻辑变换后产生脉宽调制 PWM 信号,驱动逆变器的功率开关管,从而控制 BLDC 电机各相绕组按一定顺序工作,在电机气隙中产生跳跃式旋转磁场。BLDC 转子旋转时,每转过 60°,逆变器开关管换流一次、定子磁场状态改变一次,因此 BLDC 共有 6 个磁场状态,三相各导通 120°,相电流为方波。

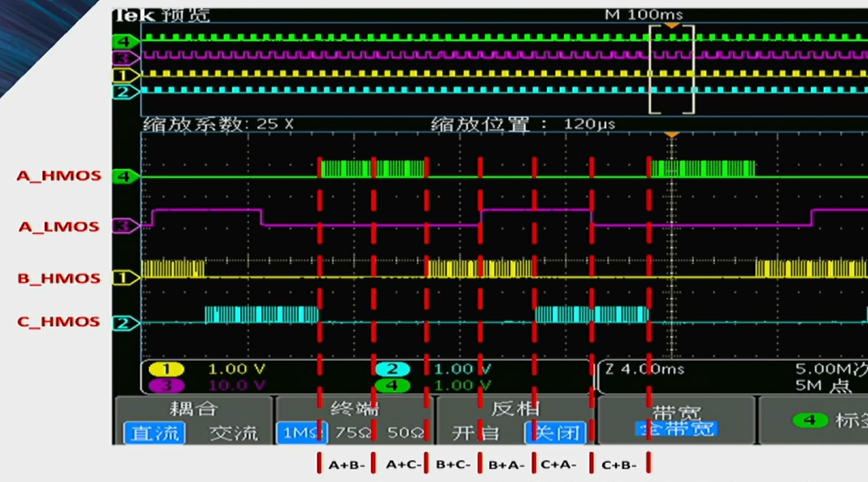

实验波形图

六步控制PWM与换相

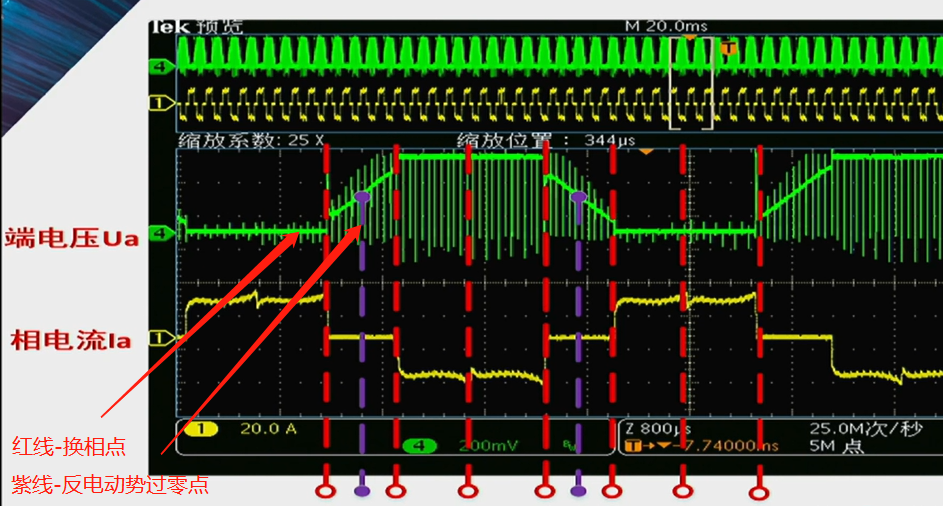

反电动势过零检测波形

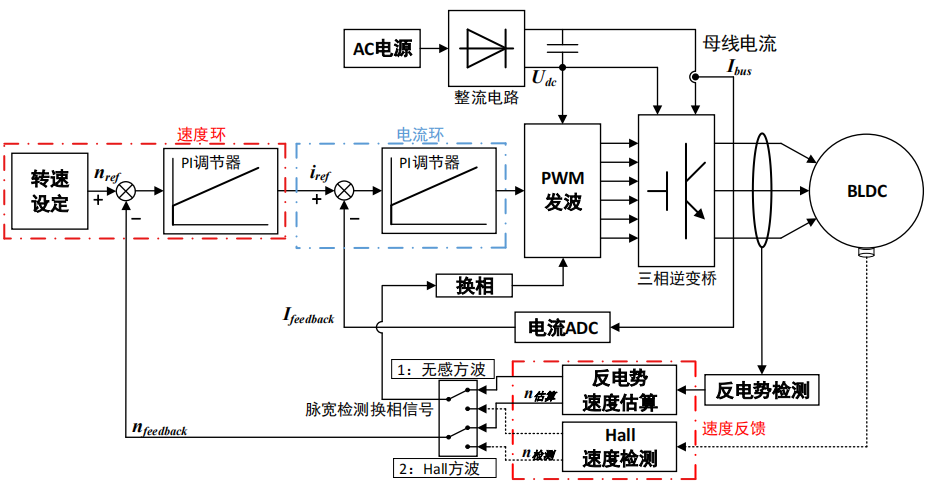

问题

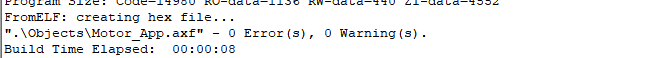

直接打开工程文档编译报错

问题都出现在spm.h这个文件里,declaration is incompatible 定义不兼容

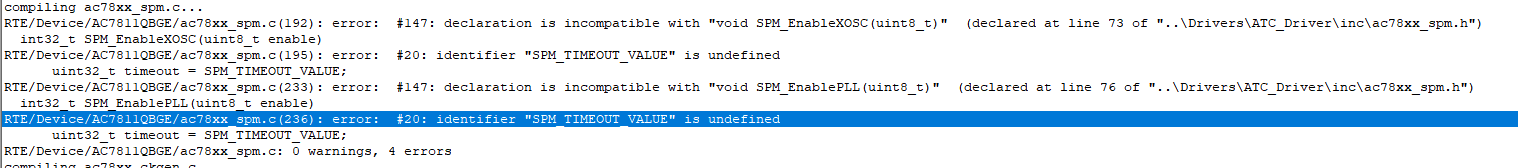

后来发现,这个头文件在即在keil的了 AC78xx 系列 MCU 的 CMSIS pack中有,又在你自己的工程文件里有,类似于重复定义,定义不兼容。

所以办法是,把包含这个头文件的路径删除。

编译成功

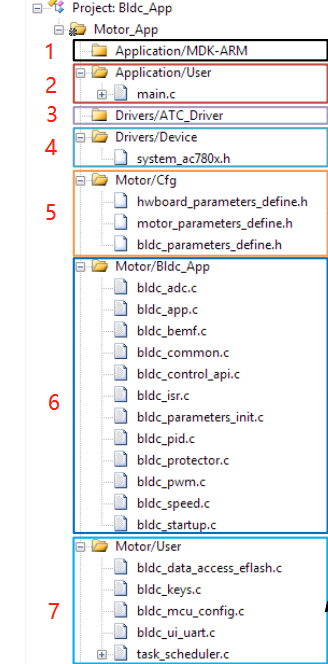

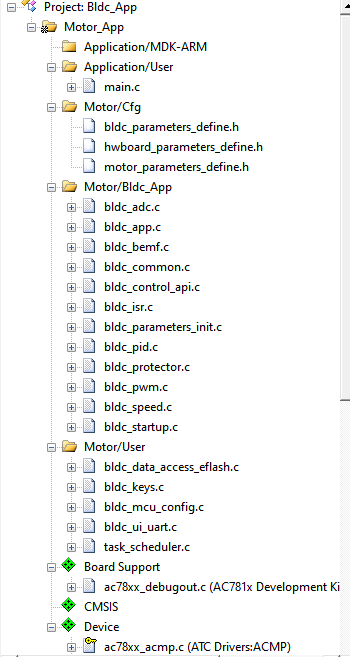

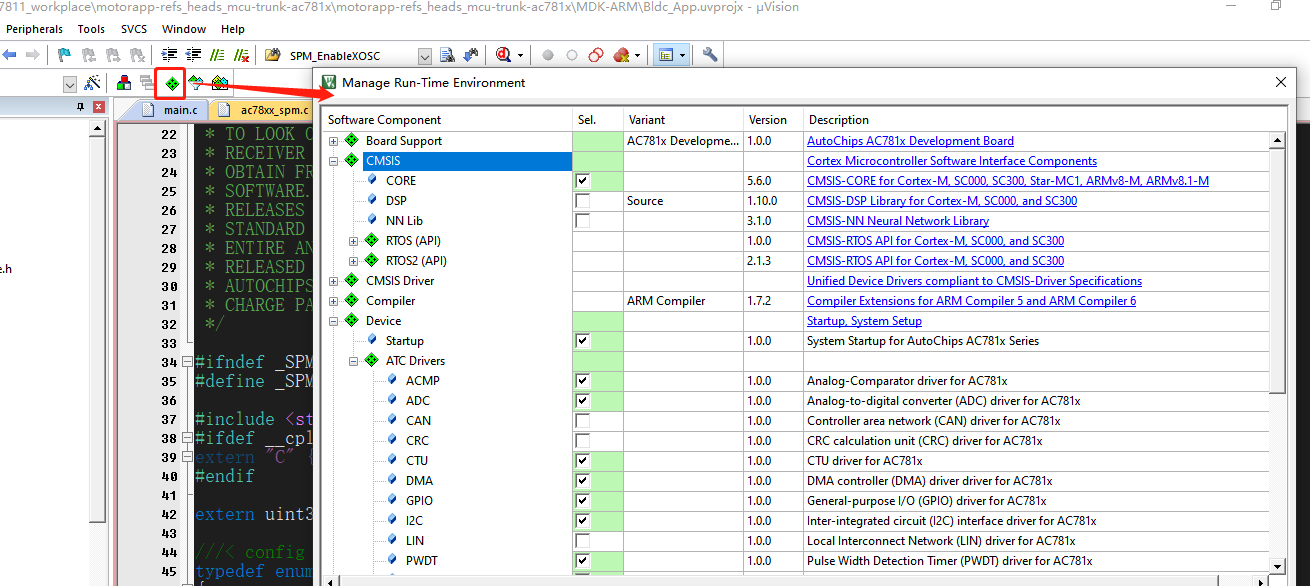

软件工程架构

出现区别的原因在于keil的CMSIS pack中已经包含了很多配置文件,就是上面右图中下边那几个绿色的四边形。你可以在keil的这里进行配置,非常的方便,但缺点是比较混乱,会与芯片厂商提供的工程文件出现一定的冲突。

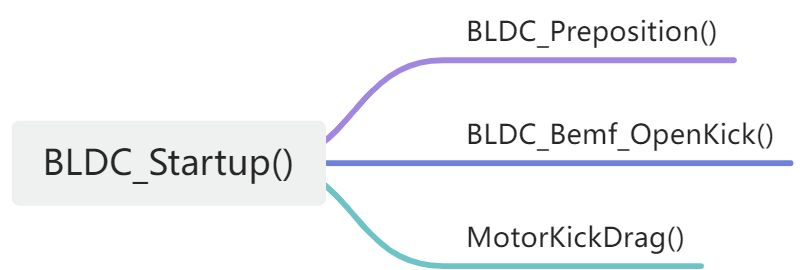

启动阶段

该模块主要是为了在启动阶段,不知道转子位置的情况下让电机先转起来,有以下两种流程:

1、预定位->开环->开环切换到闭环

2、预定位->直接闭环

无感启动预定位阶段

我们都只知道对于无感控制来讲,获取转子位置是非常重要的;

而对于BLDC的无感控制,最常用的的方法是:六部换相+反电动势过零点检测。

但是要想测反电动势测得准,精度高,就需要反电动势数值大。

这就要求在起步阶段要先把电机拉到指定位置上,先让它转起来(开环控制),等到能准确获取反电动势过零点的时候,再切换到无感控制上(闭环)。

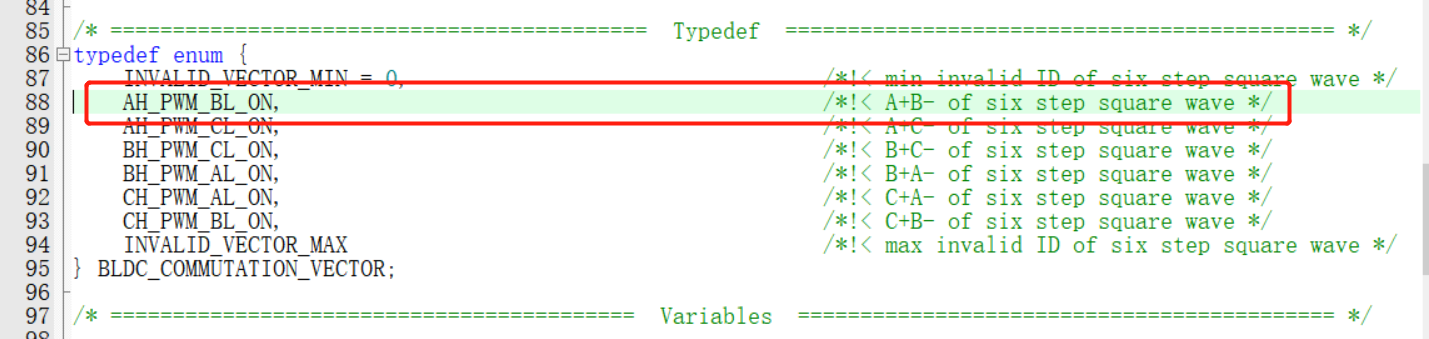

那么怎么把电机拉到指定位置上呢?具体实现代码如下:

/*!* @brief Pre-position function in bldc sensorless control.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @return none*/void BLDC_Preposition(BLDC_VARS_CTRL *bldcCtrl){uint8_t delay = INIT_PREPOSITION_DELAY ;for (bldcCtrl->setDuty = MIN_DUTY_PREPOSITION; bldcCtrl->setDuty < MAX_DUTY_PREPOSITION; bldcCtrl->setDuty += STEP_DUTY_PREPOSITION){delay -= INIT_PREPOSITION_DELAY_STEP;if (delay <= MIN_PREPOSITION_DELAY){delay = MIN_PREPOSITION_DELAY;}UpDatePwmDuty(DUTY_PERIOD(bldcCtrl->setDuty));bldcCtrl->pBemf->currentDriverVector = (uint8_t)AH_PWM_BL_ON;MosDriver(bldcCtrl->pBemf->currentDriverVector);mdelay(delay);}bldcCtrl->pBemf->kickTimeThreshold = BLDC_SENSORLESS_INIT_DELAY_TIME;}

其中核心的命令就一个:

bldcCtrl->pBemf->currentDriverVector = (uint8_t)AH_PWM_BL_ON;MosDriver(bldcCtrl->pBemf->currentDriverVector);

其实就是直接选六步中的一步,如,这里选择的是A+B-。

这样就可以把转子拉到指定位置上了。

无感启动开环阶段

在上一步完成获取转自初始位置后(实际上把他拉到某一位置上),需要赶紧让转子转起来了。

/*!* @brief bldc openkick function in bldc sensorless control, it is usually executed after obtaining the initial rotor position.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void BLDC_Bemf_OpenKick(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){if (bldcCfg->motorDir != 1)//反转{bldcCtrl->pBemf->currentDriverVector--;if (bldcCtrl->pBemf->currentDriverVector <= (uint8_t)INVALID_VECTOR_MIN){bldcCtrl->pBemf->currentDriverVector = (uint8_t)CH_PWM_BL_ON;}MosDriver(bldcCtrl->pBemf->currentDriverVector);}else//正转{bldcCtrl->pBemf->currentDriverVector++;if (bldcCtrl->pBemf->currentDriverVector >= (uint8_t)INVALID_VECTOR_MAX){bldcCtrl->pBemf->currentDriverVector = (uint8_t)AH_PWM_BL_ON;}MosDriver(bldcCtrl->pBemf->currentDriverVector);}if (bldcCtrl->setDuty <= MAX_DUTY_SENSORLESS_START){bldcCtrl->setDuty += STARTUP_DUTY_STEP;}else{bldcCtrl->setDuty = MAX_DUTY_SENSORLESS_START;}UpDatePwmDuty(DUTY_PERIOD(bldcCtrl->setDuty));}

其实就是六步换相,刚刚我们已将把转子拉到下图这个位置上了

下一步我们要先判断是让电机正转还是反转:

正转就按图示向下的顺序,当其大于INVALID_VECTOR_MAX时,拉回到最开始位置;

反转就图示向上的顺序,当其小于INVALID_VECTOR_MIN时,就跳到最后的位置。

然后就是逐渐的增加占空比,直到与设定的启动阶段最大占空比一致。

if (bldcCtrl->setDuty <= MAX_DUTY_SENSORLESS_START){bldcCtrl->setDuty += STARTUP_DUTY_STEP;}else{bldcCtrl->setDuty = MAX_DUTY_SENSORLESS_START;}UpDatePwmDuty(DUTY_PERIOD(bldcCtrl->setDuty));

从开环切入闭环控制

/*!* @brief drag motor to RUN state through open kick.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void MotorKickDrag(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){if (bldcCtrl->pBemf->kickTimeThreshold > BLDC_SENSORLESS_MIN_DELAY_TIME){bldcCtrl->bldcStartTime++;if (bldcCtrl->bldcStartTime > bldcCtrl->pBemf->kickTimeThreshold){bldcCtrl->bldcStartTime = 0;if (bldcCtrl->pBemf->kickTimeThreshold > BLDC_SENSORLESS_MIN_DELAY_TIME){bldcCtrl->pBemf->kickTimeThreshold -= BLDC_SENSORLESS_STEP_DELAY_TIME;}else{bldcCtrl->pBemf->kickTimeThreshold = BLDC_SENSORLESS_MIN_DELAY_TIME;}BLDC_Bemf_OpenKick(&g_bldcVarsCtrl, pBldcVarsCfg);}}else{if ((bldcCtrl->pBemf->currentDriverVector + bldcCfg->motorDir) >= (uint8_t)INVALID_VECTOR_MAX){bldcCtrl->pBemf->currentDriverVector = (uint8_t)AH_PWM_BL_ON;}else if ((bldcCtrl->pBemf->currentDriverVector + bldcCfg->motorDir) <= (uint8_t)INVALID_VECTOR_MIN){bldcCtrl->pBemf->currentDriverVector = (uint8_t)CH_PWM_BL_ON;}else{bldcCtrl->pBemf->currentDriverVector += bldcCfg->motorDir;}MosDriver(bldcCtrl->pBemf->currentDriverVector);SwitchAcmpChannel(bldcCtrl->pBemf->currentDriverVector);bldcCtrl->pBemf->changePhaseTime = 0;bldcCtrl->pBemf->saveChangePhaseTime = FIRST_COMMUTATE_TIME;bldcCtrl->pBemf->afterFlowTime = FIRST_STEP_DRAG_TIME;bldcCtrl->pBemf->forceChangePhaseFlag = 0;bldcCtrl->startupStatus = STARTUP_READY;}}

上来先做一个判断,开环阶段有没有执行完,没执行完继续去执行;

执行完了直接切入就行,说实话,我没看出这个阶段和开环有啥区别,唯一不同的是进行了一些传参,还有最后一个标志位STARTUP_READY的切换。

以上三个阶段怎么联系起来?

/*!* @brief BLDC motor startup function, include bldc hall and bldc sensorless control.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void BLDC_Startup(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){#if (defined BLDC_HALL)if (bldcCtrl->bldcStartTime == 0){BLDC_Hall_Startup(bldcCtrl, bldcCfg, &g_bldc_speedCmd);}if (bldcCtrl->bldcStartTime++ > 20){bldcCtrl->bldcStartTime = 0;}#elif (defined BLDC_SENSORLESS)if (bldcCtrl->pBemf->prepositonIndex < 3) /* preposition */{bldcCtrl->pBemf->prepositonIndex++;BLDC_Preposition(bldcCtrl);}else /* drag startup */{#if (defined NOKICK_STARTUP)MotorDirectDrag(bldcCtrl);#elseMotorKickDrag(bldcCtrl, bldcCfg);#endif}#else#endif}

咱们不看hall那部分,只看下边无感部分。

上来先调用了三次预定位函数,三次过后,判断你是直接切入的闭环阶段,还是经过开环再切入的闭环。

以上便是启动阶段的所有代码了

直接进入闭环

/*!* @brief drag motor dircet to RUN state, get into close loop control fast.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @return none*/void MotorDirectDrag(BLDC_VARS_CTRL *bldcCtrl){UpDatePwmDuty(DUTY_PERIOD(DRAG_DUTY));MosDriver(bldcCtrl->pBemf->currentDriverVector);SwitchAcmpChannel(bldcCtrl->pBemf->currentDriverVector);bldcCtrl->pBemf->changePhaseTime = 0;bldcCtrl->pBemf->saveChangePhaseTime = FIRST_COMMUTATE_TIME;bldcCtrl->pBemf->afterFlowTime = FIRST_STEP_DRAG_TIME;bldcCtrl->pBemf->forceChangePhaseFlag = 0;bldcCtrl->startupStatus = STARTUP_READY;}

反电动势过零点检测通道切换

在无感BLDC控制中,采集到的三相反电动势与电机中值电压在ACMP中进行比较,所以这就牵涉到三相反电动势采集时候的切换,采用轮询的方式与电机中值电压比较。

so,什么时候切换通道,进行轮询?

切换函数如下:

/*!* @brief switch acmp compared channel according to current magnetic vector, it is usually executed in bldc sensorless control.** @param[in] curDriverValue: current magnetic vector in bldc sensorless control* @return none*/void SwitchAcmpChannel(uint8_t curDriverValue){switch (curDriverValue){case AH_PWM_BL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 2);break;case AH_PWM_CL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 1);break;case BH_PWM_CL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 0);break;case BH_PWM_AL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 2);break;case CH_PWM_AL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 1);break;case CH_PWM_BL_ON:ACMP_PositiveInputSelect(ACMP_CHANNEL0, 0);break;default:break;}}

Bemf

过零点检测代码实现

/*!* @brief Check black EMF over zero point to determine when to change phase.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void BemfOverZeroCheck(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){if (bldcCfg->motorDir == 1){switch (bldcCtrl->pBemf->currentDriverVector){case AH_PWM_BL_ON:if (C_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case AH_PWM_CL_ON:if (B_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case BH_PWM_CL_ON:if (A_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case BH_PWM_AL_ON:if (C_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case CH_PWM_AL_ON:if (B_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case CH_PWM_BL_ON:if (A_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;}}else{switch (bldcCtrl->pBemf->currentDriverVector){case AH_PWM_BL_ON:if (C_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case AH_PWM_CL_ON:if (B_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case BH_PWM_CL_ON:if (A_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case BH_PWM_AL_ON:if (C_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case CH_PWM_AL_ON:if (B_PHASE_BEMF != 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;case CH_PWM_BL_ON:if (A_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;}}}

这部分代码逻辑就是,先判断正转反转,再判断处于什么换相状态,比如A+B-时,就要检测C相的反电动势是否为零。

switch (bldcCtrl->pBemf->currentDriverVector){case AH_PWM_BL_ON:if (C_PHASE_BEMF == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}break;}

这里的C_PHASE_BEMF就来自于ACMP的DR寄存器。

#define C_PHASE_BEMF ((ACMP0->DR)&ACMP0_DR_O_Msk) /*!< get phase C over zero detect results */

C向的反电动势与电机中值电压比较之后的结果。

判断为0后,开始准备换相,就是这个命令:

PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);

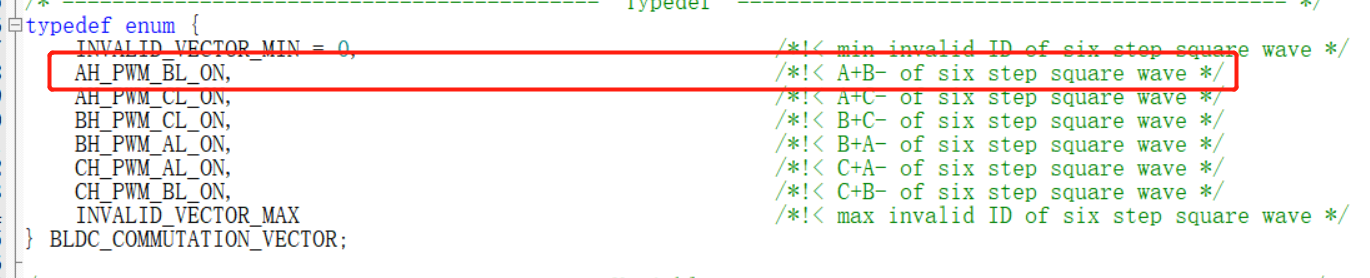

下一次换相与延时的具体时间确定

就是这个函数PrepareNextChangePhase():

下一次换相其实没什么特别的,还是根据正反转,对六步换相++—

if (motorDir == 1){curDriverValue++;if (curDriverValue >= (uint8_t)INVALID_VECTOR_MAX){curDriverValue = (uint8_t)AH_PWM_BL_ON;}}else{curDriverValue--;if (curDriverValue <= (uint8_t)INVALID_VECTOR_MIN){curDriverValue = (uint8_t)CH_PWM_BL_ON;}}

重要的在后边:

g_bemfControl.nextDriverVector = curDriverValue;g_bemfControl.delayTime = (3 * g_bemfControl.saveChangePhaseTime) >> 3;g_bemfControl.overZero_Flag = 1;

也就是这个 g_bemfControl.delayTime,我们要知道30°的电角度,对应的时间是多少,这个值就是delayTime,延迟30电角度之后再换相。具体为什么*3/8,我一直没搞懂。

换相时间那个结构体中有好几类换相时间:

uint32_t changePhaseTime; /*!< Current vector affect time count, units: 12us */uint32_t saveChangePhaseTime; /*!< Current vector affect time count saved for commutate delay, units: 12us */uint32_t lastChangePhaseTime; /*!< Last vector affect time count to determine after flow time, units: 12us */uint32_t afterFlowTime; /*!< After flow time while don't detect over zero point, units: 12us */uint32_t aveChangePhaseTime; /*!< Current vector affect average time count, units: 12us */uint32_t delayTime; /*!< Bldc delay 30 degree elec angle time count, units: 12us */BUFFER_TYPE commutationTime; /*!< Buffer to storage commutate time */

要先捋一下这几个换相时间:

changePhaseTime 当前换相时间(其实就是计数器的计数值,一个计数单元是12us)

saveChangePhaseTime当前换相时间,存下来为换相延时用

lastChangePhaseTime上一次换相时间,用来确定FlowTime?

afterFlowTime不检测过零点时,FlowTime之后

aveChangePhaseTime当前换相时间的平均值

delayTime换相延迟时间

commutationTime换相时间的缓冲区

越理感觉越乱,什么鬼这是。

是不是这个saveChangePhaseTime,指的是上次换相到这次换相之间的时间间隔?

也就是两个红线之间的时间。

开始换相

在知道下一次换相目标和需要的延时事件后,开始换相

先判断电机状态是不是‘准备好’了:

if (g_mcStatus == RUN)

之后直接执行换相

MosDriver(bldcCtrl->pBemf->nextDriverVector);

之后不要忘记轮询切换过零点的检测通道

SwitchAcmpChannel(bldcCtrl->pBemf->currentDriverVector);

然后是各种换相时间的更新以及各种标志位的清零:

bldcCtrl->pBemf->lastChangePhaseTime = bldcCtrl->pBemf->saveChangePhaseTime;bldcCtrl->pBemf->saveChangePhaseTime = bldcCtrl->pBemf->changePhaseTime;bldcCtrl->pBemf->afterFlowTime = ((bldcCtrl->pBemf->saveChangePhaseTime + bldcCtrl->pBemf->lastChangePhaseTime)) >> 3;ChangePhaseTimeCalc(&g_bldcVarsCtrl);bldcCtrl->pBemf->changePhaseTime = 0;bldcCtrl->pBemf->overZero_Flag = 0;bldcCtrl->pBemf->afterFlow_Flag = 0;bldcCtrl->pBemf->forceChangePhaseFlag = 0;

强制换相

检查一下换相间隔,是否需要强制换相。

FORCE_COMMUTATE_TIME强制换相的时间阈值,超过这个时间阈值,强制换相标志位置1.

/*!* @brief Check change phase interval to determine whether forced change phase is in needed.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void ForceChangePhaseCheck(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){if (bldcCtrl->pBemf->forceChangePhaseFlag == 0){if (bldcCtrl->pBemf->changePhaseTime > FORCE_COMMUTATE_TIME){bldcCtrl->pBemf->forceChangePhaseFlag = 1;bldcCtrl->pBemf->afterFlow_Flag = 1;if (bldcCtrl->pBemf->overZero_Flag == 0){PrepareNextChangePhase(bldcCfg->motorDir, bldcCtrl->pBemf->currentDriverVector);}}}}

串联起来

/*!* @brief Bemf over zero point detect and change phase function.** @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @return none*/void BemfCheckFun(BLDC_VARS_CTRL *bldcCtrl, BLDC_VARS_CFG *bldcCfg){ForceChangePhaseCheck(bldcCtrl, bldcCfg);//看看需不需要强制换相if (bldcCtrl->pBemf->afterFlow_Flag == 0){if (bldcCtrl->pBemf->changePhaseTime > bldcCtrl->pBemf->afterFlowTime){bldcCtrl->pBemf->afterFlow_Flag = 1;}}else//不需要强制换相,检查检查过零点{if (bldcCtrl->pBemf->overZero_Flag == 0){BemfOverZeroCheck(bldcCtrl, bldcCfg);}else//检查到过零点标志位了{if (bldcCtrl->pBemf->delayTime > 0)//实现具体的30电角度的延时{bldcCtrl->pBemf->delayTime--;}if ((bldcCtrl->pBemf->delayTime == 0) || (bldcCtrl->pBemf->forceChangePhaseFlag == 1)){//延时时间为0了,或者需要强制换相了,开始执行换相DisableInterrupts//换相的时候,一定要保证不能被中断给打断了BldcBemfChangePhase(bldcCtrl);EnableInterrupts}}}}

ADC

这部分代码主要为实现以下功能:

- @brief Bldc control bus voltage sample, get bus voltage feedback. *

- @param[in] adc: pointer to BLDC_ADC_TYPE structure

- @return none

/

void Get_VoltageValue(BLDC_ADC_TYPE adc)

{

adc->busVoltageAD = (g_ADCRegularBuffer[1] + g_ADCRegularBuffer[3]) >> 1;

adc->busVoltageTrue = (uint16_t)((uint32_t)(adc->busVoltageAD (VBUS_ATTENUATE_FACTOR VSVREF 10)) / ADC_RANGE); / 120=12V */

//VBUS_ATTENUATE_FACTOR这个数值,是你的电阻分压网络缩小的那个倍数

}

```

这个函数没什么特别的,就是电压AD数值的一个转换。注意得出的电压数值是放大10倍的。

获取总线电流

这个要稍微复杂一些,因为牵涉到一个过流的保护判断,还有滤波 ```c /*! - @brief Bldc control bus current sample, get bus current feedback. *

- @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure

- @param[in] adc: pointer to BLDC_ADC_TYPE structure

@return none / void Get_CurrentValue(BLDC_VARS_CTRL bldcCtrl, BLDC_ADC_TYPE *adc) { adc->busCurAD = g_ADCRegularBuffer[0];//获取ADC采样值

if (adc->busCurAD > adc->busCurOffset)//判断获取到的采样值是不是大于 总线电流的零点漂移busCurOffset {

if (adc->busCurAD > (int16_t)(adc->busCurOffset + LIMIT_PEAK_CUR_AD))//是的话,再判断有没有超过设定的峰值电流值{adc->busOverCurCnt++;//超过了,开始计次,看超过了几次,后边保护策略中会有判断超过10次,过流保护}else//没有超过电流峰值,要先把计数值清零{if (adc->busOverCurCnt-- <= 0){adc->busOverCurCnt = 0;}}adc->busCurAD = adc->busCurAD - adc->busCurOffset;//如果没有超过设定值,那么busCurAD就是 采集到的AD值-零点漂移

} else {

adc->busCurAD = 0;//如果采集到的电流AD还没零点飘逸的AD值大,直接拉为0

}

StorageDataCyclic(&adc->busCur, adc->busCurAD); adc->busCurAD = Filter_AverageCalc(adc->busCur.array, BUFFER_SIZE);//滤波,求平均值

adc->motorFeedbackCur = adc->busCurAD Get_EffectiveDuty(bldcCtrl) / 10000; / effective duty in 10000 times */ //Get_EffectiveDuty()有效占空比?不太懂这个值

adc->busCurTrue = (uint16_t)((int32_t)adc->motorFeedbackCur 100 / CURRENT_AD_COF); / real current in 100 times / //电流计算公式:AD反馈值100/CURRENT_AD_COF //CURRENT_AD_COF = (RSHUNT OP_AMPLIFICATION_GAIN ADC_RANGE / VSVREF) = 采样电阻 放大倍数 ADC最大范围 / 参考电压

adc->busPowerTrue = (uint16_t)(((uint32_t)adc->busCurTrue adc->busVoltageTrue) / 100); / real power in 10 times */ //功率计算

adc->motorFeedbackCurOld = adc->motorFeedbackCur; } ```

电流环PI调用

```c /*!

- @brief Bldc bus current sample and current loop PI control, executed in the RUN state *

- @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure

- @param[in] adc: pointer to BLDC_ADC_TYPE structure

@return none / void BusCurrent_Control(BLDC_VARS_CTRL bldcCtrl, BLDC_ADC_TYPE *adc) { Get_CurrentValue(bldcCtrl, adc);//获取总线电流

bldcCtrl->ibusFdkPu = adc->motorFeedbackCur CURRENT_PU_COF;//电流环反馈值,这里的CURRENT_PU_COF与上面的CURRENT_AD_COF不一样 // CURRENT_PU_COF = (uint16_t)(((uint32_t)32768 VSVREF) / (RSHUNT OP_AMPLIFICATION_GAIN ADC_RANGE * MAX_CURRENT)) //区别在于,求出AD值转化成电流值之后,又乘了一个比例关系 32768/MAX_CURRENT 2的15次方=32768 这属于Q15定点数类型的表达方式

BLDC_CurrentLoop_Calculate(pBldcVarsCfg, &g_bldc_acrPid, bldcCtrl);//进行电流环PI控制的一些计算

if (defined BLDC_HALL)

bldcCtrl->currentPwmPu = Q15_Sat(bldcCtrl->currentPwmPu, MATH_IQ(MAX_DUTY_WITH_HALL / DUTY_BASE_VALUE), MATH_IQ(MIN_DUTY_WITH_HALL / DUTY_BASE_VALUE));

else

bldcCtrl->currentPwmPu = Q15_Sat(bldcCtrl->currentPwmPu, MATH_IQ(MAX_DUTY_SENSORLESS / DUTY_BASE_VALUE), MATH_IQ(MIN_DUTY_SENSORLESS / DUTY_BASE_VALUE));

endif

UpDatePwmDuty(Q15_PERIOD(bldcCtrl->currentPwmPu));//PI调节之后的输出结果,用来进行PWM占空比的调节 } ```

Q15定点数

挺复杂一个东西,简单理解:浮点数在运算的时候是很慢很慢的,所以可以采用Q格式进行浮点数据到定点的转化,节约CPU时间。

浮点数据转化为Q15,将数据乘以2^15;Q15数据转化为浮点数据,将数据除以2^15。

具体可参考这个网址:Q格式(Q15)DSP上浮点数据定点化处理 - rockstone - 博客园

以前做总线电流采样的时候,几乎不会去考虑计算时间的问题,直接AD值到实际电流值的转换就行了,但牵涉到电流环PI调节,有大量运算的情况,就需要去考虑这个问题了,这里采用的就是把浮点数转化为Q格式。PWM

这部分代码主要功能是:

进行PWM的一些输出控制,如PWM的停止输出、PWM占空比的调节、PWM直接驱动MOS的开关等停止PWM输出

拢共分三步:PWM2的所以通道停止输出、PWM占空比设为0、PWM2软件同步 ```c /*!

- @brief Clear pwm duty and stop bldc motor. *

- @param[in] none

@return none */ void BLDC_Stop(void) { PWM2->CHOSWCR = ALL_CH_OFF; UpDatePwmDuty(0);

PWM在10000次中的有效占空比

意思就是说,你设定的PWM占空比输出值,并不代表就是实际的PWM占空比输出值,这个函数就是计算出实际的占空比输出。 ```c /*!

- @brief Get PWM module effective duty in 10000 times *

- @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure

- @return pwm effective duty

/

uint16_t Get_EffectiveDuty(BLDC_VARS_CTRL bldcCtrl)

{

uint32_t temp_PwmCh0Val;

uint32_t temp_PwmCh1Val;

uint32_t temp_PwmMcvr;

if (PWM_MODE_SELECT == PWM_COUNT_UP_DOWN_MODE)//PWM向上向下计数

else

temp_PwmCh0Val = PWM2->CHANNELS[0].CHV;temp_PwmCh1Val = PWM2->CHANNELS[1].CHV;temp_PwmMcvr = PWM2->MCVR;//MCVR是PWM计数器最大计数值#if (PHASE_UVW_POLARITY == ACTIVE_HIGH)bldcCtrl->pwmOutDuty = 10000 * (temp_PwmCh1Val - temp_PwmCh0Val) / temp_PwmMcvr;//这一部分牵涉到PWM的 组合输出模式 看下面的举例#elsebldcCtrl->pwmOutDuty = 10000 * (temp_PwmCh0Val - temp_PwmCh1Val) / temp_PwmMcvr;#endif

endif

/* enlarge 10000 times, 1234 means 12.34% */return bldcCtrl->pwmOutDuty;

}

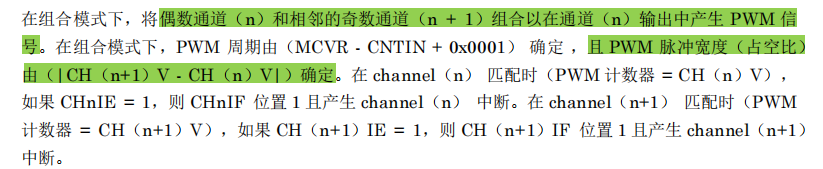

<a name="mead0"></a>### PWM的组合输出模式在组合模式下,将偶数通道(n)和相邻的奇数通道(n + 1)组合以在通道(n)输出中产生 PWM 信号。在组合模式下,PWM 周期由(MCVR - CNTIN + 0x0001) 确定 ,且 PWM 脉冲宽度(占空比)由(|CH(n+1)V - CH(n)V|)确定。<br /><br /><br />用在这里就是:10000*(3-1)/ 5 = 4000 就是40%的占空比<a name="VC0iT"></a>## PWM占空比的更新(正常情况与电流PID)这个就没什么可说的,就是调用一下PWM占空比设置函数PWM_SetChannelValue()```c/*!* @brief Update PWM output duty by manual settig or current PID calculate.** @param[in] pwmDuty: range: 0 ~ PWMx->MCVR, corresponding to 0 ~ 100% duty cycle* @return none*/void UpDatePwmDuty(uint16_t pwmDuty){if (pwmDuty > (PWM2->MCVR - 1)){pwmDuty = (PWM2->MCVR - 1);}else if (pwmDuty < 1){pwmDuty = 1;}else{}#if (defined BLDC_AFTER_FLOW_CONTROL)if (g_bemfControl.commutateState == 1){if (g_bemfControl.changePhaseTime > ((g_bemfControl.afterFlowTime * AFTER_FLOW_ANGLE_NUMERATOR) >> AFTER_FLOW_ANGLE_PSRC)){switch (g_bemfControl.currentDriverVector){case AH_PWM_BL_ON:PWM2->CHOSWCR = CH0_MODULATION_CH3_ON;break;case AH_PWM_CL_ON:PWM2->CHOSWCR = CH0_MODULATION_CH5_ON;break;case BH_PWM_CL_ON:PWM2->CHOSWCR = CH2_MODULATION_CH5_ON;break;case BH_PWM_AL_ON:PWM2->CHOSWCR = CH2_MODULATION_CH1_ON;break;case CH_PWM_AL_ON:PWM2->CHOSWCR = CH4_MODULATION_CH1_ON;break;case CH_PWM_BL_ON:PWM2->CHOSWCR = CH4_MODULATION_CH3_ON;break;default:break;}g_bemfControl.commutateState = 2;}}#endif#if (PWM_MODE_SELECT == PWM_COUNT_UP_DOWN_MODE)#else#if (PHASE_UVW_POLARITY == ACTIVE_HIGH)PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL1, (PWM_PERIOD_VALUE + pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL3, (PWM_PERIOD_VALUE + pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL5, (PWM_PERIOD_VALUE + pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL0, (PWM_PERIOD_VALUE - pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL2, (PWM_PERIOD_VALUE - pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL4, (PWM_PERIOD_VALUE - pwmDuty) >> 1);#elsePWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL1, (PWM_PERIOD_VALUE - pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL3, (PWM_PERIOD_VALUE - pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL5, (PWM_PERIOD_VALUE - pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL0, (PWM_PERIOD_VALUE + pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL2, (PWM_PERIOD_VALUE + pwmDuty) >> 1);PWM_SetChannelValue(PWM2, PWM_CHANNEL_CHANNEL4, (PWM_PERIOD_VALUE + pwmDuty) >> 1);#endif#endifPWM_SoftwareSync(PWM2);}

直接控制MOS开关

根据需要直接改变PWM输出通道,来打开对应的MOS。

/*!* @brief update PWM channel output by six step square wave magnetic vector to driver MOS.** @param[in] ChangePhaseVector: current magnetic vector in bldc control* @return none*/void MosDriver(uint8_t ChangePhaseVector){#if (defined BLDC_AFTER_FLOW_CONTROL)AfterFlow_Control(ChangePhaseVector, pBldcVarsCfg->motorDir);#elseswitch (ChangePhaseVector){case AH_PWM_BL_ON:PWM2->CHOSWCR = CH0_MODULATION_CH3_ON;PWM_SoftwareSync(PWM2);break;case AH_PWM_CL_ON:PWM2->CHOSWCR = CH0_MODULATION_CH5_ON;PWM_SoftwareSync(PWM2);break;case BH_PWM_CL_ON:PWM2->CHOSWCR = CH2_MODULATION_CH5_ON;PWM_SoftwareSync(PWM2);break;case BH_PWM_AL_ON:PWM2->CHOSWCR = CH2_MODULATION_CH1_ON;PWM_SoftwareSync(PWM2);break;case CH_PWM_AL_ON:PWM2->CHOSWCR = CH4_MODULATION_CH1_ON;PWM_SoftwareSync(PWM2);break;case CH_PWM_BL_ON:PWM2->CHOSWCR = CH4_MODULATION_CH3_ON;PWM_SoftwareSync(PWM2);break;default:break;}#endif}

Speed

设定目标转速

从rpm到Q15

/*!* @brief The per-unit value of speed targe value is calculated according to the actual value of the speed command unit rpm.** @param[in] command: pointer to SPEED_RAMP_TYPE structure* @param[in] speedCmdRpm: Given speed command unit rpm* @return none*/void BLDC_ASR_SetTargetRpm(SPEED_RAMP_TYPE *command, int16_t speedCmdRpm){command->speedTarget = (int32_t)(speedCmdRpm) * 32768 / MOTOR_MAX_SPEED_RPM;//speedTarget = 给定的实际转速rpm / 最大转速rpm * 32678 这里好像又转化成Q15定点数了}

直接Q15

/*!* @brief The per-unit value of speed targe value is calculated according to the speed command unit pu.** @param[in] command: pointer to SPEED_RAMP_TYPE structure* @param[in] speedCmdPu: Given speed command unit pu* @return none*/void BLDC_ASR_SetTargetPu(SPEED_RAMP_TYPE *command, int16_t speedCmdPu){command->speedTarget = speedCmdPu;}

设定目标加速度

/*!* @brief The per-unit value of speed ramp value is calculated according to the speed command unit pu.** @param[in] command: pointer to SPEED_RAMP_TYPE structure* @param[in] speedCmdPu: Given speed command unit pu* @return none*/void BLDC_ASR_SetRampPu(SPEED_RAMP_TYPE *command, int16_t speedCmdPu){command->speedTargetRamp = speedCmdPu;}

获取目标转速值

/*!* @brief Get the speed target value.** @param[in] speedRamp: pointer to SPEED_RAMP_TYPE structure* @return none*/int16_t BLDC_ASR_GetTargetPu(SPEED_RAMP_TYPE *speedRamp){return speedRamp->speedTarget;}

获取反馈速度值

以rpm为单位

/*!* @brief Get the feedback speed unit in Rpm.** @param[in] speed: pointer to SPEED_RAMP_TYPE structure* @return none*/int16_t BLDC_ASR_GetFbkRpm(SPEED_RAMP_TYPE *speed){return speed->speedFbkRpm;}

以pu为单位

/*!* @brief Get the feedback speed unit in Pu.** @param[in] speed: pointer to SPEED_RAMP_TYPE structure* @return none*/int16_t BLDC_ASR_GetFbkPu(SPEED_RAMP_TYPE *speed){return speed->speedFbk;}

根据设定目标速度计算加速度?

这个函数实现的是,各一个设定的rpm速度,然后可以计算出到达这一速度,所使用的加速度。

但我一直没搞懂speedTargetRamp这个参数到底什么意思?斜坡函数?加速度?

/*!* @brief Speed ramp calculation. calculate the ramp output according to the speed target value.** @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @param[in] speedRamp: pointer to SPEED_RAMP_TYPE structure* @return none*/void BLDC_ASR_RampCalc(BLDC_VARS_CFG *bldcCfg, SPEED_RAMP_TYPE *speedRamp){static uint16_t s_countSpdCmd = 0;//先判断设定的这个速度有没有超过设定的速度阈值BLDC_ASR_TargetLimit(bldcCfg->motorDir, speedRamp);s_countSpdCmd++;/* calculate speed ramp every 10ms, 9 = 10 - 1, s_countSpdCmd range is 1~10, then back to 0, and becomes to 1 after '++' */if (s_countSpdCmd > 9){s_countSpdCmd = 0;if (bldcCfg->motorDir == FORWARD_ROTATE)//正转{if ((speedRamp->speedTarget - speedRamp->speedTargetRamp) > speedRamp->speedAcceleration){speedRamp->speedTargetRamp += speedRamp->speedAcceleration;}else if ((speedRamp->speedTargetRamp - speedRamp->speedTarget) > speedRamp->speedDeceleration){speedRamp->speedTargetRamp -= speedRamp->speedDeceleration;}else{speedRamp->speedTargetRamp = speedRamp->speedTarget;}}else if (bldcCfg->motorDir == REVERSE_ROTATE){if ((speedRamp->speedTargetRamp - speedRamp->speedTarget) > speedRamp->speedAcceleration){speedRamp->speedTargetRamp -= speedRamp->speedAcceleration;}else if ((speedRamp->speedTarget - speedRamp->speedTargetRamp) > speedRamp->speedDeceleration){speedRamp->speedTargetRamp += speedRamp->speedDeceleration;}else{speedRamp->speedTargetRamp = speedRamp->speedTarget;}}else{}}}

计算转速

/*!* @brief get motor elec freq in bldc control with sensorless.** @param[in] motorDir: motor run direction* @return elec freq in Q15*/int16_t BLDC_Bemf_SpeedGet(int16_t motorDir){uint32_t s_elecFreq = 0;uint32_t s_elecFreqPu = 0;if (g_bemfControl.aveChangePhaseTime)//只要平均换相时间不为0{s_elecFreq = 166667 / (int32_t)(g_bemfControl.aveChangePhaseTime * TIMER_XUS);/* 166667 refers 6 sector time in us, 166667 = (6 / 10^-6) *///这个也比较好理解 aveChangePhaseTime是平均换相间隔(其实是一个次数值) 所以要乘以时间单元TIMER_XUS//得到的才是换一次相,费的时间(单位是us)//转一圈6次换相 所以还要*6,再把us转化成s 就是上面这个公式}s_elecFreqPu = motorDir * MATH_IQ(s_elecFreq * 1.0 / BASE_FREQ);//转化成Q15格式*2^15return s_elecFreqPu;

Protector

过流检测

/*!* @brief DC Bus over current protection. When the DC Bus current exceeds* the threshold value, DC Bus over current fault is reported.** @param[in] protect: pointer to PROTECTOR_TYPE structure* @param[in] adc: pointer to BLDC_ADC_TYPE structure* @return none*/void BLDC_Over_Current_Check(PROTECTOR_TYPE *protect, BLDC_ADC_TYPE *adc){if (adc->busOverCurCnt > BLDC_OVER_CURRENT_DBC)//电流超过电流阈值十次{protect->faultFlag.all |= (1 << OVER_CURRENT_IBUS_FAULT);//故障标志位置1}else{}}

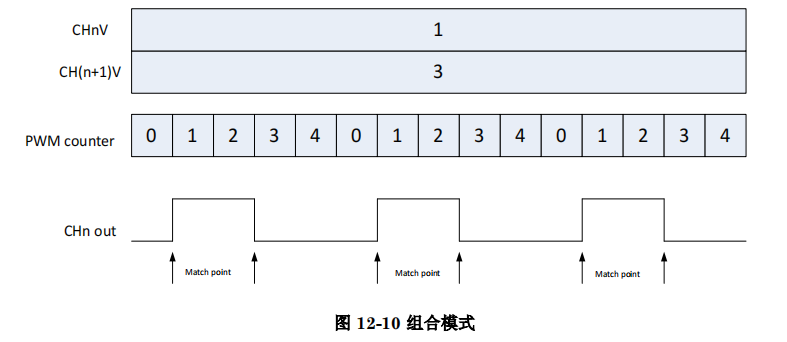

过压欠压检测

电压保护策略方面,主要就是过压与欠压的检测(过压与欠压原理相似放一起说)

代码给不同的电压设定了三个状态:DETECT_FAULT、DETECT_OK、DETECT_UNKNOWN

除了设定这样一个恢复阈值之外,还牵涉了一个s_debounce参数,这个参数是用来消抖的,简单理解,就是延时,不会因为电压的跳变,突然就出现保护。

/*!* @brief DC Bus over voltage protection. When the bus voltage is higher than* threshold value, Undervoltage fault is reported, and it will return* to normal operation after the bus voltage rises to the recovery threshold.** @param[in] protect: pointer to PROTECTOR_TYPE structure* @param[in] volt: DC Bus voltage value, 10 times the real value* @return none*/void BLDC_Over_Voltage_Check(PROTECTOR_TYPE *protect, uint16_t volt){static int16_t s_vbusStatus = BUS_VOLTAGE_NORMAL;static int16_t s_prevVbusStatus = BUS_VOLTAGE_NORMAL;static int16_t s_debounce = 0;// static int16_t s_status = DETECT_OK;if (volt > OVER_VBUS_THRESHOLD){s_vbusStatus = BUS_VOLTAGE_OVER;}else if (volt < OVER_VBUS_RECOVERY_THRESHOLD){if (s_vbusStatus == BUS_VOLTAGE_OVER){s_vbusStatus = BUS_VOLTAGE_RECOVER;}}else{}if (s_vbusStatus != s_prevVbusStatus){s_prevVbusStatus = s_vbusStatus;s_debounce = 0;}else{if (s_vbusStatus == BUS_VOLTAGE_RECOVER){if (s_debounce < 10){s_debounce++;}else{// g_mcStatus = STOP;s_vbusStatus = BUS_VOLTAGE_NORMAL;protect->faultFlag.all &= ~(1 << VBUS_OVER_VOLTAGE_FAULT);}}else if (s_vbusStatus == BUS_VOLTAGE_NORMAL){if (s_debounce < 10){s_debounce++;}else{// s_status = DETECT_OK;protect->faultFlag.all &= ~(1 << VBUS_OVER_VOLTAGE_FAULT);}}else{if (s_debounce < 10){s_debounce++;}else{// s_status = DIAGNOSTIC_FAIL;protect->faultFlag.all |= (1 << VBUS_OVER_VOLTAGE_FAULT);}}}// return s_status;}

串起来

故障检查以什么样的时基单元进行检查。

/*!* @brief Motor protection main function. The corresponding protection functions* are implemented according to different time bases.** @param[in] none* @return none*/void BLDC_Motor_Protection(void){#if (defined BLDC_OVER_CURRENT_CHECK)/* DC Bus over current protection , 1ms*/BLDC_Over_Current_Check(&g_bldc_protector, &g_bldc_adSample);#endif#if (defined BLDC_UNDER_VOLTAGE_CHECK)/* DC Bus under voltage protection, 1ms */BLDC_Under_Voltage_Check(&g_bldc_protector, g_bldc_adSample.busVoltageTrue);#endif#if (defined BLDC_OVER_VOLTAGE_CHECK)/* DC Bus over voltage protection, 1ms */BLDC_Over_Voltage_Check(&g_bldc_protector, g_bldc_adSample.busVoltageTrue);#endifif (g_bldc_protector.faultFlag.all)//检测到故障位了,电机停转{BLDC_Stop();g_mcStatus = FAULT;}return;}

PID

PI计算

/*!* @brief Pid calculate of motor control.** @param[in] pid: pointer to PID_TYPE structure* @return none*/int16_t PID_Calculate(PID_TYPE *pid){int32_t min;int32_t max;pid->pPidOutput->errPu = pid->pPidInput->refPu - pid->pPidInput->fbkPu;//误差 设定值-反馈值/* proportional term */pid->pPidOutput->upPu = MATH_Mpy(pid->pPidOutput->errPu, pid->pPidCoef->kpPu);//比例:kp*误差 再转化成Q15格式/* integral term */pid->pPidOutput->uiPu += MATH_Mpy(pid->pPidOutput->errPu, pid->pPidCoef->kiPu);//积分:ki*kp 再转化为Q15格式/* saturate integral output with a dynamic limit 带有动态限制的饱和积分输出*/max = pid->pPidInput->maxPu - pid->pPidOutput->upPu;max = Q15_Sat(max, max, 0);min = pid->pPidInput->minPu - pid->pPidOutput->upPu;min = Q15_Sat(min, 0, min);pid->pPidOutput->uiPu = Q15_Sat(pid->pPidOutput->uiPu, max, min);/* calculate total output */pid->pPidOutput->outPu = pid->pPidOutput->upPu + pid->pPidOutput->uiPu;//计算总的比例 与 积分的变化/* saturate total output 饱和总输出 */pid->pPidOutput->outPu = Q15_Sat(pid->pPidOutput->outPu, pid->pPidInput->maxPu, pid->pPidInput->minPu);return (int16_t)pid->pPidOutput->outPu;}

有几个疑问的计算公式:

#define Q15_Max(x, y) (x > y ? y : x)//很显然不太对啊这#define Q15_Min(x, y) (x < y ? y : x)#define Q15_Sat(A, P, N) (Q15_Max(Q15_Min(A, N), P))//取最大值?

速度环

/*!* @brief Speed loop processing of motor control.** @param[in] speed: pointer to SPEED_RAMP_HANDLE structure* @param[in] pid: pointer to PID_TYPE structure* @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @return none*/void BLDC_SpeedLoop_Calculate(SPEED_RAMP_TYPE *speed, PID_TYPE *pid, BLDC_VARS_CTRL *bldcCtrl){Set_BLDC_PidRef(pid, speed->speedTargetRamp);//设定速度参考值Set_BLDC_PidFbk(pid, speed->speedFbk);//设定速度反馈值bldcCtrl->ibusRefPu = PID_Calculate(pid);//ibusRefPu电流环参考值 是不是意味着其实速度环还是靠电流环来调节占空比的}

电流环

/*!* @brief Current loop processing of motor control.** @param[in] bldcCfg: pointer to BLDC_VARS_CFG structure* @param[in] pid: pointer to PID_TYPE structure* @param[in] bldcCtrl: pointer to BLDC_VARS_CTRL structure* @return none*/void BLDC_CurrentLoop_Calculate(BLDC_VARS_CFG *bldcCfg, PID_TYPE *pid, BLDC_VARS_CTRL *bldcCtrl){Set_BLDC_PidRef(pid, (bldcCfg->motorDir * bldcCtrl->ibusRefPu));Set_BLDC_PidFbk(pid, bldcCtrl->ibusFdkPu);bldcCtrl->currentPwmPu = PID_Calculate(pid);}

Contral_api

这个模块是电机控制参数的一些初始化,比如速度环与电流环的PI值、电机初始状态等,没什么特别的。

Bldc_app

这个模块除了一些电机、板子和控制参数的初始化外,还有任务调度方面的函数与代码,这里重点讲一讲。

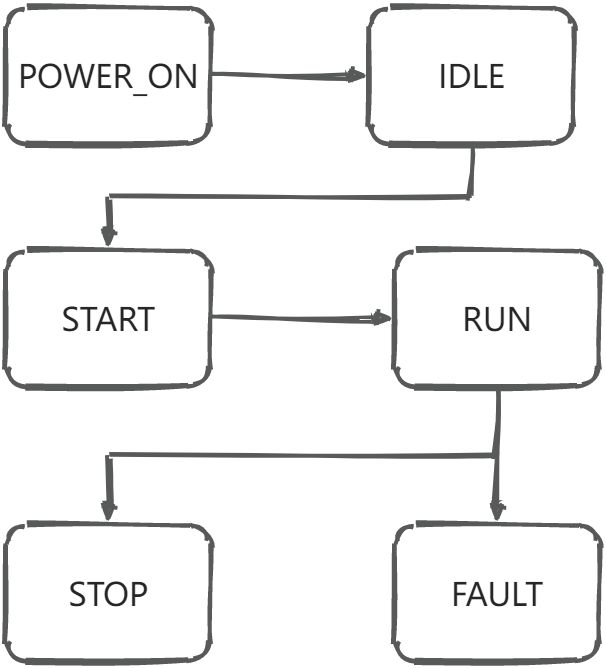

电机状态切换

/*!* @brief The Main state machine, used to set the running state of the bldc control system.** @param[in] none* @return none*/void BldcStateMachine(void){switch (g_mcStatus){case POWER_ON:BLDC_Parameters_Initialize();// BLDC_ASR_CommandInit(pBldcVarsCfg, &g_bldc_speedCmd);BLDC_ASR_CommandSet(pBldcVarsCfg, &g_bldc_speedCmd);#if (defined DATA_ACCESS_FLASH_ENABLE)g_flashOperationStatus = Eflash_DataAccess_DefaultSave(&g_dataAccessFlash);if (g_flashOperationStatus == EFLASH_STATUS_SUCCESS){Eflash_DataAccess_PowerOnRecovery(&g_dataAccessFlash);Eflash_DataAccessEflashInit(&g_dataAccessFlash);g_mcStatus = IDLE;}#elseg_mcStatus = IDLE;#endifbreak;case IDLE:BLDC_Parameters_Initialize();#if (defined DATA_ACCESS_FLASH_ENABLE)if (g_dataAccessFlash.eraseEnable == 1){g_mcStatus = FLASH_TASK;}#endifif ((g_bldc_speedCmd.speedTarget * pBldcVarsCfg->motorDir) < 0){g_bldc_speedCmd.speedTarget = 0 - g_bldc_speedCmd.speedTarget;g_bldc_speedCmd.speedTargetRamp = 0 - g_bldc_speedCmd.speedTargetRamp;}break;case START:BLDC_Startup(&g_bldcVarsCtrl, pBldcVarsCfg);if (BLDC_Get_Startup_Status(&g_bldcVarsCtrl) == STARTUP_READY){g_mcStatus = RUN;}else if (BLDC_Get_Startup_Status(&g_bldcVarsCtrl) == STARTUP_FAIL){g_mcStatus = IDLE;}else{}break;case RUN:BLDC_SpeedTask();break;case STOP:BLDC_Stop();BLDC_Parameters_Initialize();// BLDC_ASR_CommandInit(pBldcVarsCfg, &g_bldc_speedCmd);BLDC_ASR_CommandSet(pBldcVarsCfg, &g_bldc_speedCmd);g_mcStatus = IDLE;break;case FAULT:BLDC_Stop();if (g_bldc_protector.faultFlag.all == 0){g_mcStatus = STOP;}break;#if (defined DATA_ACCESS_FLASH_ENABLE)case FLASH_TASK:g_flashOperationStatus = Eflash_DataAccessEflashProcess(&g_dataAccessFlash);if (g_flashOperationStatus == EFLASH_STATUS_SUCCESS){g_mcStatus = IDLE;g_flashOperationStatus = EFLASH_STATUS_ACK;Eflash_DataAccessEflashInit(&g_dataAccessFlash);g_flashTaskFinish = 1;}break;#endifdefault:break;}}

task_scheduler

核心

最关键的核心函数

/*!* @brief Task scheduler main processer, called by Main function.** @param[in] none* @return none*/void Task_Scheduler(void){/* Notice: the delay of each task sequency cannot be the same! *//** We can add a new time base task as the follow type:* SCH_Add_Task(New_task_function, task_sequence_number, task_time_base);* where New_task_function is the name of the task name;* task_sequence_number is the position of the task in all task sequences;* task_time_base is the time base of the task, indicating its execution cycle.*//* 1ms time base tasks */SCH_Add_Task(Task0_1ms, 0, 1);/* 2ms time base tasks */SCH_Add_Task(Task1_2ms, 1, 2);/* 10ms time base tasks, reserve */SCH_Add_Task(Task2_10ms, 2, 10);/* 100ms time base tasks, reserve */SCH_Add_Task(Task3_100ms, 3, 100);/* 1s time base tasks, reserve */SCH_Add_Task(Task4_1000ms, 4, 1000);/* 2s time base tasks, only used in FOC */SCH_Add_Task(Task5_2000ms, 5, 2000);while (1){SCH_Dispatch_Tasks();//任务调度MC_Keys_Read();//按键扫描}}

任务调度

*!* @brief Dispatch the tasks.** @param[in] none* @return none*/void SCH_Dispatch_Tasks(void){uint8_t index;/* Dispatches (runs) the next task (if one is ready) */for (index = 0; index < SCH_TASKS_SEQUENCE_MAX; index++){if (g_SchTask[index].runOrder > 0){/* Run the task */(*g_SchTask[index].pTask)();/* Reset / reduce runOrder flag */g_SchTask[index].runOrder -= 1;/* Periodic tasks will be scheduled to run again *//* if this is a 'one shot' task, remove it from the array */if (g_SchTask[index].period == 0){SCH_Delete_Task(index);}}}/* Report system status */SCH_Report_Status();}

key

这个就是按键控制逻辑了,就一个函数:

/*!* @brief Get the response of pressing each key on the control board.* The keys action are judged by the ADC value:* when ADC value is in [ 0, START_STOP_MAX ], it corresponds to the Start / Stop key;* when ADC value is in [ FORWARD_REVERSE_MIN, FORWARD_REVERSE_MAX ], it corresponds to the Forward / Reverse key;* when ADC value is in [ FAST_MIN, FAST_MAX ], it corresponds to the Fast key;* when ADC value is in [ SLOW_MIN, SLOW_MAX ], it corresponds to the Slow key.** @param[in] none* @return none*/void MC_Keys_Read(void){if ((!GPIO_GetPinValue(KEY_START_STOP)) && (!s_keyStartPressed))//开始、停止{s_keyStartPressed = 1;}else if (s_keyStartPressed && GPIO_GetPinValue(KEY_START_STOP)){s_keyStartPressed = 0;if (g_mcStatus == IDLE){g_mcStatus = START;}else{g_mcStatus = STOP;}}else if ((!GPIO_GetPinValue(KEY_DIRECTION)) && (!s_keyDirPressed))//方向{s_keyDirPressed = 1;}else if ((GPIO_GetPinValue(KEY_DIRECTION)) && (s_keyDirPressed)){s_keyDirPressed = 0;if (pBldcVarsCfg->motorDir == 1){pBldcVarsCfg->motorDir = -1;}else{pBldcVarsCfg->motorDir = 1;}// g_bldc_speedCmd.speedTarget = MATH_Abs(g_bldc_speedCmd.speedTarget) * pBldcVarsCfg->motorDir;}else if ((!GPIO_GetPinValue(KEY_SPEED_UP)) && (!s_keyUpPressed))//加速{s_keyUpPressed = 1;}else if ((GPIO_GetPinValue(KEY_SPEED_UP)) && (s_keyUpPressed)){s_keyUpPressed = 0;g_bldc_speedCmd.speedTarget += (pBldcVarsCfg->motorDir * SPEED_CHANGE_STEP);}else if ((!GPIO_GetPinValue(KEY_SPEED_DOWN)) && (!s_keyDownPressed))//减速{s_keyDownPressed = 1;}else if ((GPIO_GetPinValue(KEY_SPEED_DOWN)) && (s_keyDownPressed)){s_keyDownPressed = 0;g_bldc_speedCmd.speedTarget -= (pBldcVarsCfg->motorDir * SPEED_CHANGE_STEP);}else{/* do nothing */}}

BLDC无感方波控制